DRAKE PLASTICS LTD. CO. GAINS AEROSPACE INDUSTRY AS9100D(2016) QUALITY SYSTEM CERTIFICATION

May 5, 2021

May 5, 2021, Cypress, TX – Drake Plastics Ltd. Co. has been awarded certification as a manufacturer of extruded shapes and precision parts under AS9100D(2016) Certification, an international quality management system that includes the ISO 9001:2015 standard and additional requirements for the aerospace industry. The achievement puts Drake Plastics in esteemed company. Of the million plus organizations worldwide that are ISO 9001 certified, less than 2% hold AS9100D certifications. “Our compliance enables us to meet the rigorous demands of aviation, space and defense clients worldwide,” states Drake Plastics President, Steven Quance. “It also elevates our quality systems and procedures to ...

Read More →

Drake Plastics Ltd. Co. Adds Precision Waterjet Cutting

February 3, 2021

Drake Plastics Ltd. Co., the global leader in ultra-performance polymer stock shape extrusion, is once again expanding its capabilities. To better serve machine shop and distribution customers, Drake has added precision waterjet cutting of blanks and 2D parts.

Read More →

What Is A Polyamide-imide?

November 1, 2019

Polyamide-imides (PAI) are high performance polymers that combine excellent high temperature strength with low temperature toughness and impact strength while offering exceptional chemical resistance as an amorphous polymer to a wide range of common chemicals. They are closely related to two other high temperature aromatic imide polymers, polyetherimides (PEI) and polyimides (PI). The most recognized polyamide-imide polymer is Torlon, which was introduced in the 1970s by Amoco as an extension of a low molecular polymer offered to enhance the adhesion of fluoropolymer in cookware such as Silverstone® and as wire coatings.

Read More →

Selecting Materials And Processes For High Performance Plastic Parts

July 30, 2019

This paper is intended to help design engineers and those within the plastics industry supporting them select the process sequence and materials that maximize the performance of service critical parts. A great deal of folklore exists within the plastics community regarding the relative differences between machined and injection molded plastic parts. This lore is easy to understand given datasheet values published by resin and shape producers. The values listed on resin datasheets are almost always greater than those published by leading shapes suppliers (http://bit.ly/datasheetreview). Don’t let that observation distract or slow down your mission to design and manufacture the best ...

Read More →

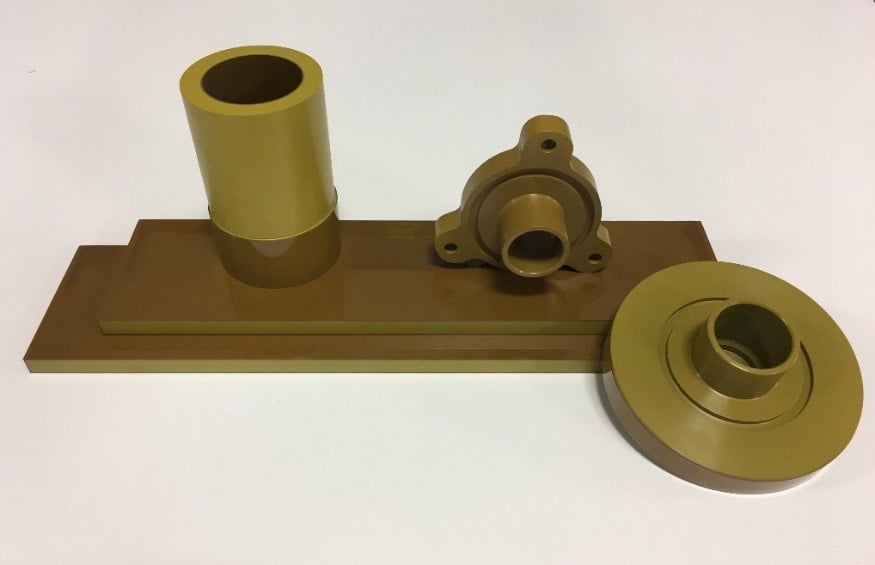

Thinking Lean! Reducing The Cost Of Manufacturing High Performance Polymer Parts Using Drake’s Seamless Tube®.

April 5, 2019

Starting with the right size and shape based on final part geometry is critical when working with materials like Torlon®, PEEK and polyimides that are inherently expensive. Did you know that an extra .25” on a diameter can add 25% or more to the cost of your raw material? This waste is compounded by a machinist spending time removing extra stock. Add in extra tool wear, especially in glass or carbon fiber reinforced materials, and the unnecessary cost related to using a less than optimal size can exceed 50%.

Read More →

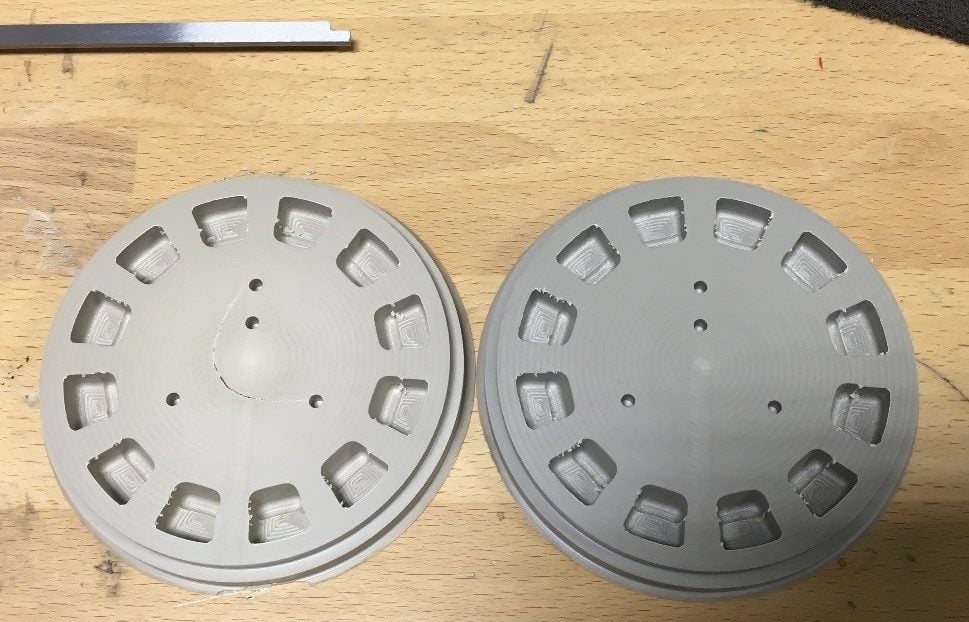

Making The Best Even Better. Post Curing Torlon Wear Parts Reduces Wear

March 25, 2019

High PV bearing applications are tough for even high-performance polymers like Torlon, PEEK and PPS. The reason is simple; frictional heat generated especially by the velocity component of “P x V” does not dissipate as easily as does in inherently more conductive bearing materials (i.e. metals). The heat begins to soften the polymer, thermally expanding it. In most constrained bearings (think journal bearings/bushings or plane bearings) the plastic, with higher CLTE than the metal constraining it, has nowhere to go and collapses onto the shaft or piston. Excessive heat builds up, eventually causes bearing failure by over heating or excessive ...

Read More →

Large Diameter PEEK Challenges? Drake’s Large Diameter Reinforced PEEK Rod Is “The Solution”

February 19, 2019

Ever hear from a customer… “I just started drilling and I heard a crack” or “I was sawing and melted plastic (swarf) stopped the blade” or “my inspection department found cracks in all my parts”. I can even tell you what the “mill” likely said… “They were using the wrong size drill or the wrong feed rate or the saw blade was the wrong type or they should have annealed the material in between operations.” We used to say that until we recently helped out a customer requesting another mill’s 4” diameter GL30 rod. Check out the results of Drake’s ...

Read More →

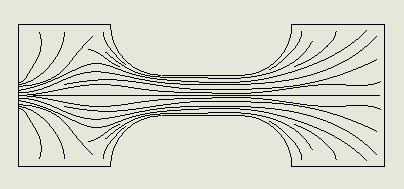

Understanding Datasheet Properties to Maximize Part Performance

February 19, 2019

Producing parts from extruded stock shapes is preferred when injection molding is not practical, and many times for part performance reasons. Experienced plastics engineers have learned that the performance of a machined part can far exceeds that of an injection molded part, yet a comparison of resin and shape datasheets causes one to conclude the exact opposite. Why do the properties of extruded shapes rarely match the properties listed on a resin datasheet? Understanding orientation related to material flow especially when using fiber-reinforced grades is the key to understanding this observation. Molecular orientation due to melt flow profiles also impacts ...

Read More →

Drake Motorsports Development – High Performance Polymer Parts for Racers

March 28, 2018

CYPRESS, Texas, March 23, 2018 (GLOBE NEWSWIRE)—Drake Motorsports Development, LLC was recently formed to accelerate the availability of track proven race parts and to continually develop new racing products from a racing industry insider perspective. The first part developed is an offset control arm bushing machined from Torlon 4435. The bushing delivers an increased static negative camber range of adjustment for the front wheels, which is used as a suspension tuning method to optimize tire contact under high lateral loads. Tyler Quance, owner of Drake Motorsports Development, and the Engineering Manager for Drake Plastics, has been racing a Spec Miata ...

Read More →

Introducing Drake PAI 4200 (Natural Polyamide-imide), When Purity Matters

March 28, 2018

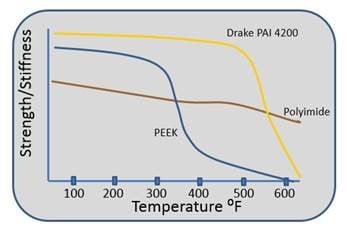

CYPRESS, Texas, March 21, 2018 (GLOBE NEWSWIRE)–Drake Plastics Ltd Co. announces the introduction of Drake PAI 4200, a new grade of PAI which is available in Rod, Plate and Seamless Tube for machining, as well as offering injection molded parts. Drake PAI 4200 is Torlon 4000 T resin which has been compounded into pellets, making it suitable for extrusion or injection molding. Drake PAI 4200 is a temperature extreme capable, high purity and high-performance thermoplastic for parts requiring the performance of unreinforced PAI such as Torlon 4203, but without the TiO2 which is considered a potential contaminant in some applications. ...

Read More →