What is Ultem 4001 PEI?

Ultem 4001 PEI is formulated with PTFE as an internal lubricant. It gives engineers and designers the high performance inherent with the polyetherimide polymer coupled with significantly more wear resistance.

Like all Ultem grades, Ultem 4001 is a melt-processable amorphous high-performance thermoplastic. The resin formulation is opaque. Standard colors are black and natural light brown, and custom colors are available. It is RoHS compliant.

All Ultem grades including Ultem 4001 offer high structural strength, and resistance to creep under load at elevated temperatures. They carry UL 94 V0 and 94 5VA flammability ratings, resist a broad range of chemicals and exhibit good toughness on impact. Fiber-reinforced Ultem PEI grades such as Ultem 2300 available from Drake in the form of Seamless Tube® are also available.

Chemically, PEI is a polyetherimide. It falls within the family of polyimide polymers that includes Torlon PAI (polyamide-imide) and Vespel PI (polyimide). These higher-performance imides have higher strength and rigidity at higher temperatures, and are inherently wear-resistant, whereas Ultem 4001 PEI achieves this with PTFE integrated into its formulation.

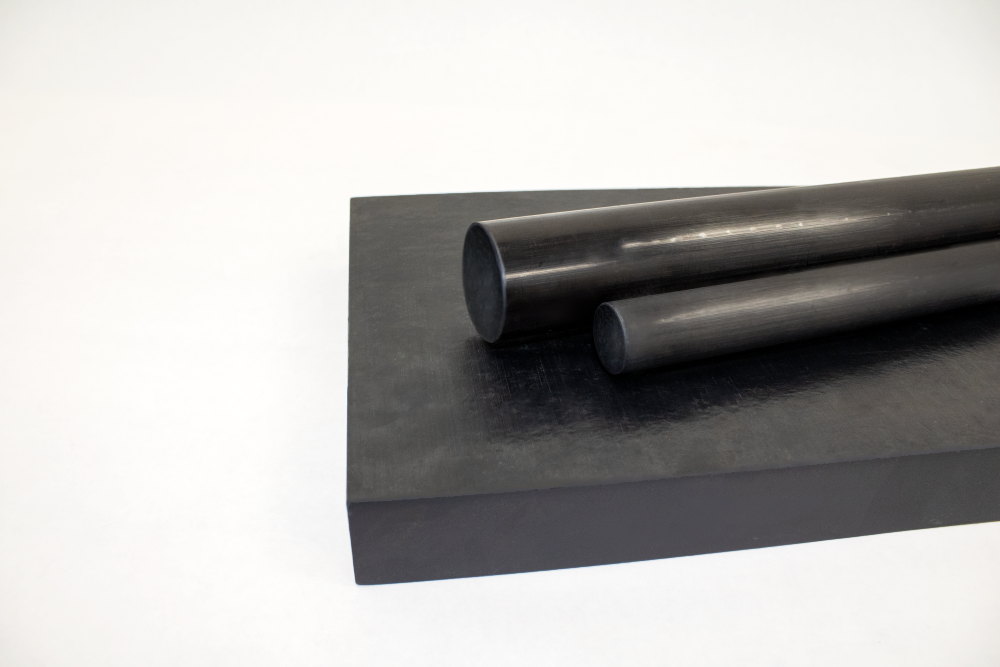

What Products Does Drake Offer in Ultem 4001?

Drake converts Ultem 4001 resin into semi-finished shapes by melt extrusion, and offers an array of sizes and configurations. The extruded rod and plate products are then machined into precision components that serve a diverse applications. With its versatile manufacturing capabilities based in one location, Drake also offers the ability to transition from precision prototypes to production parts made by machining or injection molding.

How do the properties of Ultem 4001 compare to Ultem 1000?

The PTFE content of the Ultem 4001 PEI formulation adds bearing and wear resistance to the inherently high performance of Ultem PEI. This internal lubricant has only a minor effect on the other attributes of the polymer, including its mechanical properties and its heat resistance, as the comparison to standard unfilled Ultem 1000 in Table 1 shows.

Table 1. Properties Comparison:

Standard Ultem 1000 PEI vs. wear-resistant Ultem 4001 PEI

| Property | Test Method | Units | Ultem 1000 | Ultem 4001 |

| Specific Gravity | ASTM D 792 | g/cc | 1.27 | 1.33 |

| Hardness | ASTM D 785 | Rockwell M | 109 | 110 |

| Tensile Strength @ yield | ASTM D 638 | MPa psi |

110 16,000 |

103 14,900 |

| Elongation @ Break | ASTM D 638 | % | 60 | 40 |

| Flexural Modulus | ASTM D 790 | MPa ksi |

3510 509 |

3400 493 |

| Flexural Yield Strength | ASTM D 790 | MPa ksi |

165 23,900 |

151 21,900 |

| Izod Impact, Notched | ASTM D 256 | J/cm ft-lb/in |

0.530 0.993 |

1.17 2.19 |

| Heat Deflection Temp @ 1.8MPa | ASTM D 648 | °C °F |

201 394 |

200 392 |

| Glass Transition Temp. (Tg) | °C °F |

217 423 |

217 423 |

|

| Taber Abrasion | ASTM D 1044 | mg loss /1000 cycles | 10.0 | 2.0 |

| K-factor xE-10, PV=2000 | Resin supplier (Sabic) test method | psi-fpm vs steel | NA | 72 |

| K-factor xE-10, PV=2000 | Resin supplier (Sabic) test method | psi-fpm vs self | NA | 27 |

| Coefficient of Friction on steel, Kinetic | ASTM D 1894 | 0.42 | 0.25 | |

| Flammability | UL94 | 94V0 ≥ 0.75mm 5VA ≥ 3.0mm |

94V0 ≥ 0.38mm 5VA ≥ 1.5mm |

|

| Oxygen Index | ISO 4589 | % | 47 | 48 |

Note: Data based on industry-standard test methods or tests developed by the resin supplier, and intended as a general comparison only. Applications must be tested under actual end-use conditions to validate performance of components made from any plastic material.

The high wear resistance of Ultem 4001 is its major advantage over Ultem 1000.

High temperature applications where a component is in contact with itself or metals under dynamic load can benefit from the bearing and wear resistance of Ultem 4001.

Wear (K factor) data is unavailable for Ultem 1000 for a direct comparison. The Taber Abrasion values however, show a significant performance improvement with Ultem 4001, as do the coefficient of friction data.

Engineering note:

Ultem 4001 has a higher glass-transition temperature than PEEK.

The softening point or glass-transition temperature (Tg) of Ultem 4001 is 217oC, nearly 70oC higher than the Tg of PEEK at 150oC. Its thermal properties including its Tg 217C coupled with its wear resistance can make Ultem 4001 a candidate for dynamic load bearing applications where PEEK may fall short on thermal performance, and where chemical exposure is compatible with the PEI polymer.

Rigidity of Ultem 4001 is higher than most amorphous plastics.

Among amorphous thermoplastics, the flexural modulus of unreinforced Ultem PEI is exceptional. In addition, the internal lubricant in Ultem 4001 PEI has only a negligible effect on this property as Table 1 shows. These properties are significantly higher than those of other high performance amorphous plastics such as PSU and PPSU, and compare favorably to the stiffness of unreinforced PEEK at 3500 MPa.

Ultem 4001 is rated UL 94V0 and 5VA on flammability resistance.

As with other PEI grades, Ultem 4001 is inherently flame retardant and requires no flame retardant additives to achieve its UL 94V0 and 5VA ratings. It also has an oxygen index or LOI of 48%.

Chemical resistance exceeds most amorphous thermoplastics.

The PEI polymer resists a far greater range of chemicals than other amorphous thermoplastics. Ultem 4001 PEI is no exception. In fact, the PTFE additive improves Ultem PEI’s inherent chemical resistance. It performs well in most commercial automotive and aircraft fluids, fully halogenated hydrocarbons, alcohols and weak aqueous solutions. However, its chemical resistance is more limited than that of PEEK and other semi-crystalline materials, and it should not be used in components exposed to strong alkaline environments or partially halogenated hydrocarbons.

As with any material, components made from Ultem 4001 that see prolonged chemical exposure must be evaluated under actual in-use conditions to validate performance in use.

What are the other significant properties of Ultem 4001?

Typical properties of Ultem PEI grades including Ultem 4001 include:

- Excellent dielectric strength

- Durability and lightweight

- Stable electrical properties

- High dimensional stability

- Low water absorption

- No halogenated flame-retardant additives

What types of applications would benefit from Ultem 4001?

Its high structural strength, flammability ratings and thermal properties position Ultem 4001 as a candidate for bearing and wear components that require creep resistance over a wide temperature range. In compatible chemical environments, Ultem 4001 can also serve as an upgrade to PEEK in an application that requires higher temperature resistance. Functional applications serving diverse industries include:

- Wear pads and other sliding surface components

- Rollers and bushings in electrical equipment

- High temperature robotics applications

- Dynamic load-bearing components in medical diagnostic equipment

- Liquid metering equipment components