Drake Plastics Adds Ryton® R-4 to Product Array

March 29, 2017

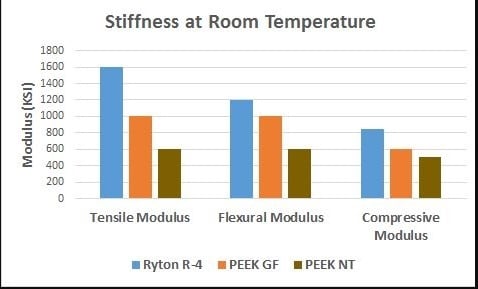

CYPRESS, TX–(Marketwired – March 14, 2017) – Drake Plastics Ltd. Co. announces the availability of extruded Ryton® R-4-240 PPS shapes from ½” up to 3″ diameter for machined parts. Ryton’s strength, stiffness and chemical inertness in a wide range of environments makes it suitable for applications ranging from the oil and gas and automotive industries to the aerospace industry. There are no known solvents for Ryton® PPS under 200°C. Additionally it offers a heat distortion temperature of 265°C, among the highest of the thermoplastics and room temperature stiffness that exceeds both glass reinforced PEEK and Torlon®. Ryton® has been used ...

Read More →

Drake Plastics Races with Torlon

March 24, 2017

CYPRESS, TX–(Marketwired – March 07, 2017) – Drake Plastics is a leader in providing innovative plastic solutions to solve engineering challenges. Combining a love of cars with their passion for high performance polymers, Drake Plastics has announced a Race Team to facilitate the adoption of Torlon and PEEK components in the racing industry. Tyler Quance, Drake’s R&D Manager is leading the effort with a Mazda Miata equipped with a BP-4W, inline DOHC engine that he races on the NASA Texas circuit. Background Torlon’s pedigree in racing has long been publicized, but Torlon products have yet to become mainstream in the ...

Read More →

Celebrating 20 Years!

June 17, 2016

Drake Plastics celebrates its 20th Anniversary by recognizing all teammates and especially the contribution of the dedicated folks who were with us in the early years. Steve, Francisco, Art, Cindy, Faye, Romo Jr., Francisco Jr., Pam, Annie, Stacy and Tom are among Drake’s first employees! Twenty years ago, DVD’s were just being introduced, Fed Interest Rates were over 8% and Torlon 4203 and 4301 were the only grades available in rod up to 2” diameter and plate up to 1” thickness. Today Drake’s team of more than 40 plastics professionals, sets the pace for specialty shapes extrusion by offering Torlon ...

Read More →

Larger Diameter Torlon Yields Material Savings

May 17, 2016

Drake Plastics has once again increased the size availability of extruded Torlon shapes for machined parts by completing an order for 10 inch diameter rod for support of a major aerospace customer. Prior to this development the largest size was 7.625 inch diameter rod which was introduced by Drake in 2015. Weighing in at over 210 pounds (95 Kg) per 48” length, the 10 inch/ 255 mm diameter Torlon 4203 rod again expands the opportunity for design engineers to specify machined Torlon parts for their most demanding applications according to Steve Quance. Always driven by customer needs, Drake made ...

Read More →

Drake Plastics Launches Drake Plastics Medical

February 29, 2016

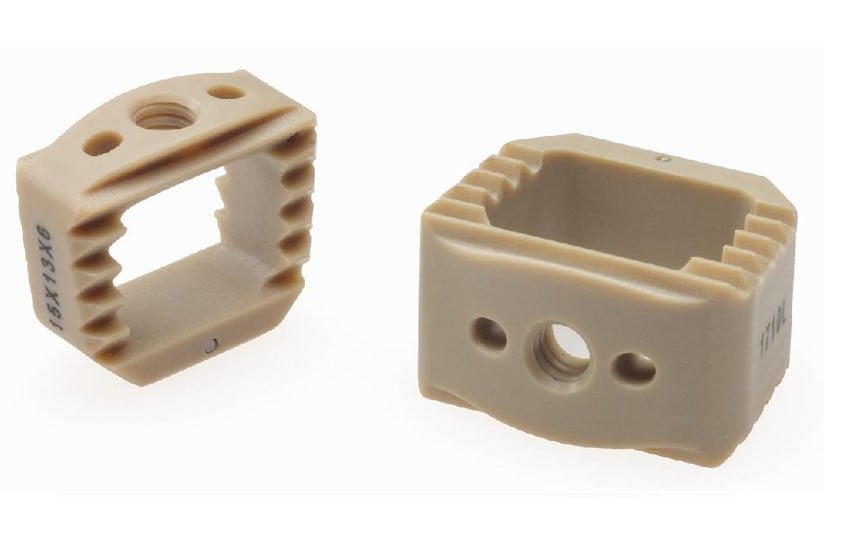

CYPRESS, TX, February 2016—Drake Plastics announces the formation of Drake Plastics Medical to better serve the specialized requirements of the medical device and life science industries. Drake Plastics Medical will match the innovative processing expertise, for which Drake Plastics has been recognized, with a quality management system that meets the requirements of ISO 13485. Drake Plastics Medical is currently ISO 9001-2008. Drake Plastics Medical will enhance the performance and reliability of our customers’ products by: • Utilizing in-house extrusion, molding and machining combined with material knowledge to help customers select the right material and process from concept through production • ...

Read More →

Drake Plastics Introduces Seal Segments™ for PEEK and Torlon

February 16, 2016

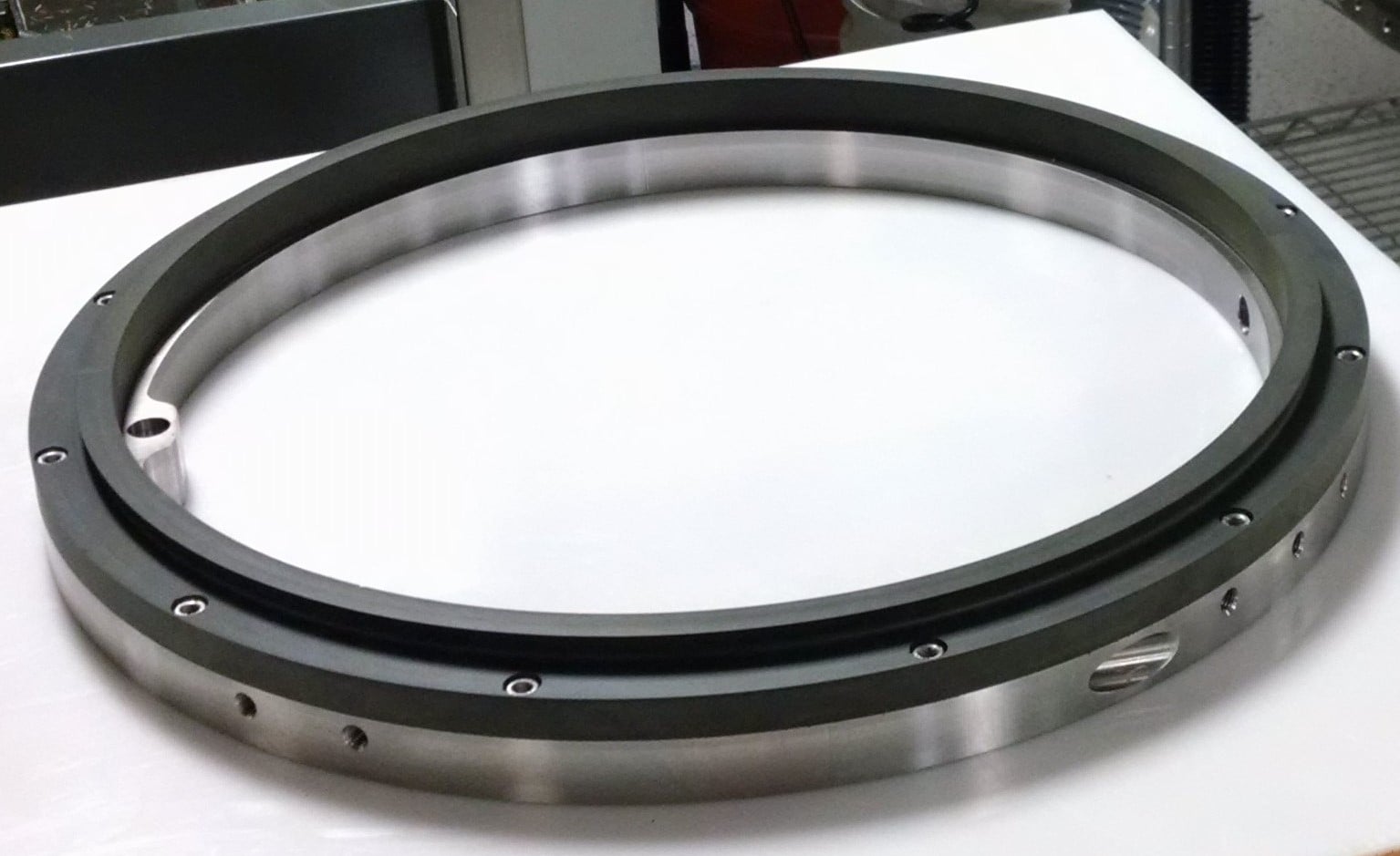

Drake Plastics proprietary melt process yields Seal Segments™ with superior physical properties over compression molded materials. The two-piece split segment construction improves performance and reduces cost. Seal Segments™ by Drake Plastics are available in all Torlon and PEEK Grades. Cypress, Texas, February 2016—Drake Plastics’ Product & Process Development team recently developed a process to produce Seal Segments™ for finish machining into split or segmented seals, bearings, labyrinth seals and thrust washers. Seal Segments™ can be made from 12” (300 mm) minimum up to 200” (5,000 mm) maximum diameter. Seal Segments™ enabled Torlon 4301 to be used in a dynamic ...

Read More →

Drake Adds AvaSpire To Product Family

February 2, 2016

Drake Plastics is pleased to offer AvaSpire® PAEK machinable shapes and injection molded parts. AvaSpire is complementary to Drake’s Torlon and PEEK materials, solving performance gaps in addition to offering improved aesthetics and economics. CYPRESS,TX January 2016—Drake Plastics is pleased to announce the addition of Solvay’s AvaSpire® PEAK, a hybrid PEEK product to the array of high-performance machinable shapes and injection molded products offered by Drake. “AvaSpire is complementary to our Torlon and PEEK based materials and bridging the performance gap between PEEK and Torlon,” says Commercial Director, Mike Oliveto. AvaSpire, the newest addition to Solvay’s portfolio of Ultra Polymers ...

Read More →

Thick Torlon bar-1.350″ (34 mm)

December 18, 2015

An electrical component used on the F-22 fighter required a heavier cross-section than had previously been produced in Torlon 5030. Drake designed and built tooling, developed the process, and delivered this new size within six weeks.

Read More →

Torlon High Pressure Hydraulic Components

December 18, 2015

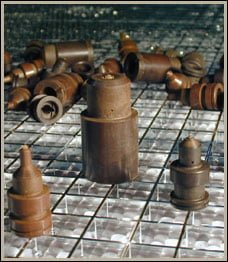

Precision machined Torlon poppets, seats and spools operate at 5000 psi (34 Mpa) and extend service life. Increased operating pressures enable significant system cost savings and weight reduction.

Read More →

Torlon Can Mandrels

December 18, 2015

Drake’s Seamless Tube® capability has been used to solve dimensional stability and service life problems in the printing of two-piece aluminum cans. Drake is working in close cooperation with North America’s leading fabricator of can mandrels, Blair Machine and Tool Co.

Read More →