Ever hear from a customer… “I just started drilling and I heard a crack” or “I was sawing and melted plastic (swarf) stopped the blade” or “my inspection department found cracks in all my parts”.

I can even tell you what the “mill” likely said… “They were using the wrong size drill or the wrong feed rate or the saw blade was the wrong type or they should have annealed the material in between operations.”

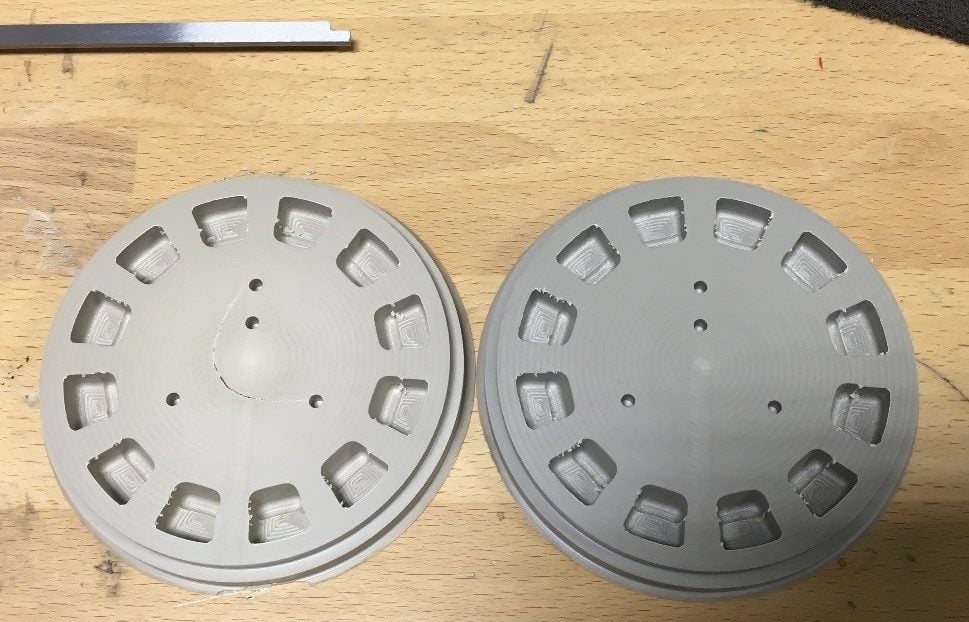

We used to say that until we recently helped out a customer requesting another mill’s 4” diameter GL30 rod. Check out the results of Drake’s 4” diameter KT820GF30 and some one else’s 450GL30 run consecutively in the exact same machine with the same program and tooling.

Still don’t believe it… Check out the video of our guys running parts. https://www.youtube.com/watch?v=6CTtlMjOIa4

The good news is we were able to salvage the parts since the finished part had a large enough ID.

Why the difference?

Extrusion processing of high temperature materials like PEEK require diligent processing including very slow rates as the melted polymer must cool from its melt temperature above 630F to ambient temperatures. This temperature gradient sets up very high thermal stresses in the material. Combine these thermal stresses with extrusion pressures and crystallization stresses that are inherent to semi-crystalline materials like PEEK and you have the makings of a real processing challenge. Now add reinforcements like glass and/or carbon fiber which reduce the toughness (elongation) and you now have a perfect storm. Time has proven…”Less than ideal extrusion processing cannot be overcome by annealing after extrusion”.

Drake’s single piece flow approach to all our extrusion processes and our 2 decades of experience processing Torlon helped us develop the right combination of resin and process to make the most machineable large diameter PEEK shapes available anywhere in the world. Our processing is focused on running at minimal pressures and rates needed to ensure full density with maximum toughness and ductility rather than to achieve the highest run rates. Drake’s proprietary extruder design developed for running Torlon PAI makes achieving this delicate balance possible. Any remaining residual stress is minimized by our carefully monitored annealing cycle, again a skill learned fine tuning our process for extruding the largest Torlon shapes in the world.

What role does resin choice play?

Our experience points to processing advantages with Solvay’s KT PEEK grades especially when processing larger diameter rods and thicker cross section plates. The higher molecular weight and broader distribution of molecular weights provides better toughness/impact resistance to withstand stresses associated with the extrusion process. Illustrating this, Drake produces both Victrex and Solvay carbon reinforced PEEK rod but the Victrex CA PEEK is only offered up to 1” diameter while the KT820CF PEEK rod is extruded up to 6.5” diameter rod with plans to go even larger.

We currently stock 4, 4.5, 5, 5.5, 6 and 6.5” diameter rod in natural, 30% glass reinforced and 30% carbon fiber reinforced virgin PEEK.

- Only looking for small quantities. We stock in 60 inch lengths but will cut to your length as needed

- You’d rather not saw cut blanks. No problem, we’ll cut blanks too using our precision Cosan saw.

- Using someone else’s rod already but looking for a better material. You provide the details and we’ll provide the sample.