Customers often approach Drake Plastics about transferring a mold to our operation. In many instances, the customer believes the mold no longer works or never did. In other cases, the polymer materials specification changed to a resin with which the incumbent molder had no experience or did not have the equipment required to process it. Another common reason customers have mold tools transferred to us is their historical molder is not able or willing to meet tougher inspection or certification requirements such as CMMC compliance.

Whatever the reason, our Injection Molding and Engineering team’s experience and recommendations have built a successful record in getting existing tools back to work, producing parts well beyond our customers’ expectations.

What is a Mold Transfer?

When an injection molding company has a job they are no longer willing or able to produce, or have priced the part beyond its reasonable value because of production difficulties, the mold may be moved to another company. This is what’s known as a mold transfer.

The receiving company must have the technical skills to evaluate the mold’s production-worthiness for the thermoplastic specified and the willingness and ability to overcome the obstacles the incumbent injection molding company couldn’t or wouldn’t. The new molder should also have the expertise to make upgrades or modifications that can bring the mold to optimum functionality

What are Typical Reasons for Transferring a Mold?

Transferring an injection mold can be a prudent decision. Experienced mold designers with expertise in processing the polymers involved can often resolve perceived problems.

These are some typical reasons behind mold transfers to Drake Plastics, and the solutions we’ve provided to get the supply of parts back on track quickly:

Problem: Existing molder does not want to invest in meeting new certification, regulatory, industry or customer requirements.

OEMs sometimes have to step up to changes in regulatory requirements that extend to the manufacturing process for the equipment’s component parts. Some injection molding companies may elect not to make the investments required for compliance, forcing the OEM to find a new source for the parts.

Solution:

Supporting customers on rigorous quality and certification requirements – including modifications – is essential to serving high technology industries like aerospace, defense, energy and semiconductor manufacturing. Drake Plastics has decades of success in these arenas, and a reputation for flexing quickly to respond to changes. Our baseline for quality systems is our certification to the aerospace industry’s AS9100D(2016) and ISO 9001:2015 standards. Drake Plastics also offers CMMC (Cybersecurity Maturity Model Certification), ITAR (International Traffic in Arms Regulations) and DFARS (Defense Federal Acquisition Regulation Supplement) compliance and registrations. We apply our full breadth of quality system expertise and compliance to all customers regardless of industry.

Problem: Changes to a material specification.

Engineering upgrades to machinery or equipment can mean specifying a different polymer formulation to improve the performance of individual molded parts. The new grade may contain additives for better bearing and wear properties, or fiber reinforcement for added strength. These changes can make it difficult to mold the new grade in the original tool. Or the new specification may call for an alternative high-performance polymer with different melt characteristics.

Solution:

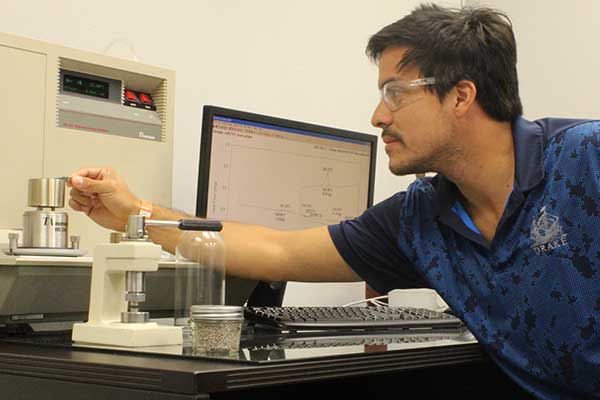

Drake Plastics can analyze and define melt flow behavior of advanced polymers in our laboratory. We use mold flow analysis to understand the changes needed to make the part in the new material. This analysis can determine how tooling that’s transferred to us can be modified for the new grade of material specified.

Problem: The molder’s machines are inadequate.

Even with properly built tooling, injection molders inexperienced in high-performance polymers may have problems producing good parts. Each advanced polymer formulation has a unique set of process temperatures, pressures and melt dwell times required for consistently high quality production. Molding machines that can’t process these polymers at prescribed conditions are likely to produce parts with voids, porosity and degraded material. An ideal mold won’t compensate.

Solution:

Drake Plastics designs and builds our processing equipment specifically for ultra high-performance plastics. The equipment line-up in our operation gives customers a versatile range of part sizes from 0.85 to 570 grams (0.03 to 20 oz.). Investments in quality assurance include injection-compression technology that eliminates the risk of voids common in heavy wall sections. In addition, our process control technology incorporates probes within molds to monitor process conditions and maintain them at optimum levels for each polymer formulation.

Problem: Improper tool design and construction for the specified polymer.

This can be a particular problem when a company is inexperienced in tooling and molding for ultra high-performance plastics like Torlon PAI, Victrex and Solvay PEEK, XT PEEK, “HT” PEK, AvaSpire PAEK, Ultem PEI and Ryton PPS. Tooling must be tailored to the melt profile of the specific grade of the advanced polymer to achieve the highest possible levels of quality and performance in molded parts. Otherwise, missed delivery commitments and erratic quality can result.

Solution:

This is an area where Drake Plastics excels, with nearly three decades of processing experience in diverse formulations of these challenging plastics. We are also a Solvay-approved injection molder of Torlon. Our technology in melt flow analysis and our years of production history give our engineering team the know-how to assess whether a mold can produce consistently high quality parts in the specified polymer. From there, we can evaluate options to optimize the existing tool or whether to invest in a new one.

Problem: Worn or damaged tooling.

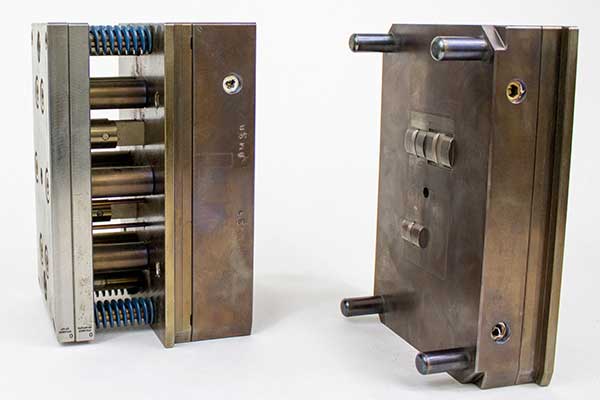

Components of a mold can wear out or become damaged and need rework beyond the capabilities of the original molding shop. Often, the original molder recommends scrapping the tool entirely in favor of a new one, or the customer shifts the job to another shop to build the new mold.

Solution:

Drake Plastics’ culture of lean manufacturing focuses on getting the most out of the equipment investments we and our customers make. Our team has the skills to restore or rebuild transferred tools to optimal condition, and prioritizes that approach rather than obsoleting the tool.

Problem: The original molder exits the business.

It happens. The molder may simply cease operating. Or the company may decide that molding parts in a challenging polymer formulation no longer fits their business priorities. In some cases, the complex processing conditions required for advanced thermoplastics conflicts with goals for production output. They look to exit the job and move the tooling elsewhere.

Solution:

Our business is fully invested in processing high-performance polymers, and we base our growth on serving historical applications while constantly developing new ones. Customers can rely on Drake Plastics to work with the original company to make mold transfers involving these polymers as efficient and seamless as possible. Our experience in advanced polymer processing and mold design enables us to assess all aspects of the tooling and recommend modifications that yield parts well within specifications.

How Does Drake Plastics Manage Mold Transfers?

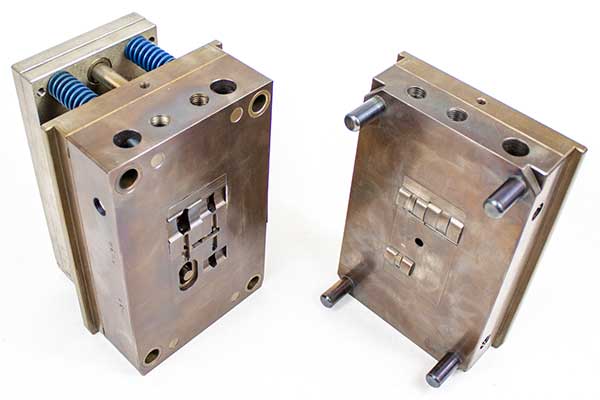

Our engineers ask customers for as much information as possible on the tool and part design, material and related requirements. Part drawings, photos of molds and actual molded parts are very helpful. After a step-by-step evaluation, we provide a detailed plan for their mold transfer and a ballpark estimate of cost. When the mold arrives, we disassemble it for evaluation and provide a firm proposal.

Step one: Get the customer’s or current molder’s assessment of the tooling.

- Is the tooling wrong for the job?

- What problems were encountered?

- Is the tooling worn or damaged and no longer functional?

- Is the injection molding equipment itself inadequate?

- Does the current molder simply want to transfer the job, and if so, why?

Step two: Evaluate the design of tools and fixtures.

- 3D files of the mold are most useful if available. If not, model files of the molded part are usually sufficient.

- 1st preference: Solidworks or Parasolid file type allows us to look at every component.

- 2nd preference: file types designated .igs or .stp.

- 2D files (e.g., pdf) are also useful in addition, or if 3D files are not available.

- If tool and fixture design files are not available, the following will help evaluate tooling:

- Photos of the inside and outside of the tooling, with a dimensional scale for reference.

- Inventory and description of all components available with the tooling:

- Full mold base size

- Modular unit die size

- Cavity and core set size

Step 3: Evaluate the design of the molded part.

- 3D files are best if available.

- Parasolid preferred, or .igs, .stp, or .step

- 2D file (e.g., pdf ) of the design print with dimensional tolerances.

Step 4: Define the material specification and related requirements.

- All available information on the grade of the thermoplastic specified.

- Any supporting information on the material specification.

- g., requirements for post-curing, annealing.

- Specific quality or regulatory requirements.

Step 5: Define other requirements related to the job.

- Post-molding:

- Finish machining, laser marking, special cleaning or packaging.

- Sample parts:

- Machined prototype parts.

- As-molded; as-molded and finished.

- Process documentation requirements:

- Injection processing specifications.

- Secondary operation processing specifications.

- First Article Inspection documentation.

What Can Customers Expect after Our Evaluation?

Our engineering team provides customers with an assessment that covers:

- Whether the tooling is satisfactory for molding high quality parts to specification in the grade of material required.

- Recommended tool modifications if needed, and a quote for cost and timing for upgrading the tooling.

- A quotation for producing parts to specification and services that may be required, such as finish machining, packaging and special certifications.

Getting Customers Back into Production Quickly

While our tooling assessment is thorough, it is also fast and efficient. Drake Plastics understands the need for urgency in getting our customers’ parts back into production. Our growing list of customers reflects this commitment and our track record of delivering on it.

What Are the Benefits of a Mold Transfer?

Transferring an injection molding tool to Drake Plastics can have a dramatic impact on the capital cost to produce a part, assuming the mold can be used as-is or salvaged by reworking it. Revitalizing an existing tool also minimizes the time a tool is out of production, vs. designing, building and validating a new one. The key to a clear decision is working with an injection molder on the receiving end who has the depth of experience in processing the specified thermoplastic resin, and the creativity and skills to work with the existing tooling to make parts to specification without having to start from scratch.