When injection molded properly, parts made from advanced polymers like Torlon PAI, PEEK, Ultem PEI, Ryton PPS perform dependably in extreme environments that are hostile even to many metals. They provide unparalleled levels of reliability and longevity for applications ranging from precision seals in down-hole oil and gas tools to semiconductor chip manufacturing and test apparatus to deep space telescope mechanisms.

Technical data sheets for these materials provide a general picture of their performance potential. However, the transition from properties data to an injection molded component involves variables that determine how the polymer actually performs in the finished part. Key factors include properly designed and maintained injection mold tools, resin drying and confirmation of moisture content, contaminant-free material handling, the injection molding machine technology, and precision controls that maintain optimum process conditions for the resin grade. Another critical element is the expertise of the process engineering and production team.

Why are High-Performance Polymers Challenging to Injection Mold?

Torlon PAI, PEEK, Ultem PEI, Ryton PPS and other advanced polymers have a high melting point and a narrow melt temperature processing window. In any polymer, its melt temperature corresponds to the temperature at which it begins to degrade. If the dwell time in the melt phase exceeds prescribed limits, significant degradation and loss of physical properties occurs. This is why it is important to properly size the molding machine to the parts being molded. Too large of a machine translates to a high volume of melt with excessive residence time in the barrel for the number of shots required. Too small of a machine will mean insufficient residence time to fully melt the resin pellets. It can also lack the clamp force to hold an oversized mold closed during the injection cycle.

To achieve optimum performance and quality in these premium polymers, temperatures must be scientifically established and precisely maintained throughout the duration of the injection molding run.

Adding to the challenge is the availability of high-performance plastics in multiple formulations. The specialized grades allow engineers to zero in on a set of properties that delivers the optimum balance of cost and performance for their application. For example, Torlon PAI and PEEK resin producers offer high strength fiber reinforced grades, EMI or RFI shielding and static dissipation formulations, and grades with solid lubricants that reduce friction and extend the life of bearing and wear components. In some cases, grades have multiple additives that improve a combination of properties. While the diversity provides an expanded range of performance benefits, it also poses a challenge: the type and level of the additive integrated into a polymer formulation determines the specific processing conditions that will achieve its full performance capabilities.

What Factors Define a Capable Injection Molder for Advanced Polymers?

An assessment based on the following factors can help identify an injection molding operation that can produce parts with consistently high quality and performance in the specified advanced polymer and grade:

Engineers and Operators with Dedicated Expertise in Advanced Polymers

Maintaining consistently high efficiency, quality and service reliability comes down to the expertise of the injection molding team, regardless of the production equipment. It can also be the most difficult factor for a prospective customer to gauge.

These indicators can help identify an injection molder whose engineers and operators are up to the challenge.

- Molder Certifications Well-respected certification programs that validate a high level of expertise and competency in injection molding advanced polymers include:

- RJG Master Molder® Certification: RJG, a global full-service injection molding solutions company, provides a two-level Master Molder® certification program for process engineers and technicians responsible for injection molding operations.

- Torlon® PAI Certified Molder Program: Syensqo (formerly Solvay), has awarded its certification for competence in injection molding its Torlon® PAI resins to a limited number of companies. The requirements encompass the quality management system, process technology and equipment, and the molder’s successful track record in serving OEMs who specify the advanced polymer for their applications.

- Key customer retention and recognition

OEMs who specify advanced polymers for their applications are generally in high technology industries such as aerospace, medical, semicon and defense. Their equipment must function under extreme conditions with no compromise in the performance of each molded part. Clear evidence of a long-standing working relationship with customers in these types of industries is a good indicator of an injection molder’s expertise and performance. Recognition awards from OEMs and inclusion on their key supplier panels also demonstrate an injection molder’s positive track record and value.

- Specialization and focus

As with many specialized fields, a team dedicated to processing high-performance plastics will develop the expertise to continually raise the bar on production efficiency, quality and consistency with these materials. Indicators include in-house engineered and built equipment, and improvements to off-the-shelf machinery. On the shop floor, an on-going focus on lean manufacturing, quality, delivery reliability and customer satisfaction indicates a capable operations team.

Proper Equipment and Production Environment

The following factors contribute to achieving consistently high performance and quality in parts injection molded from high-performance plastics:

- Molding machines with a range of tonnages

An operation with machines in a diverse range of tonnages can provide a single source for multiple part sizes required for a complete assembly. It can also make it easier to transition to next-generation parts that differ in size and complexity. A range of tonnages also ensures the right balance of machine to part sizes.

- Injection-compression capability

Injection-compression technology eliminates voids in parts with thick cross-sections. This can be particularly important where homogeneous material distribution in thick walls is essential to optimize strength.

- All-electric injection molding machines

All-electric injection molding machines are noted for greater precision, repeatability and faster cycle times compared to hydraulic presses. Their more precise control of molding conditions is an advantage for parts with exceptionally tight tolerances. All-electric machines also eliminate the risk of hydraulic fluid contaminating resin pellets and finished parts.

- Process control technology

Once process conditions are defined for a high-performance thermoplastic, maintaining the optimum melt temperature and pressure throughout the production run is essential. This requires process control systems and transducers that can monitor and immediately adjust melt conditions in the molding machine’s barrel and in the mold cavity itself. The investment pays major dividends in quality, performance, productivity and supply assurance.

- Dedicated resin dryers

Drying pelletized resins – and maintaining prescribed dryness – are essential to prevent voids and defects in high-performance thermoplastic parts.

An investment in dryers dedicated to specific polymers is an added benefit. It eliminates the risk of cross-contamination with an incompatible resin that may either degrade or not fully melt while processing the specified material. Either problem can negatively affect performance and aesthetics of finished parts.

- Post-curing and annealing capabilities

Post-curing or post-annealing injection molded parts under precise conditions specific to the advanced polymer can achieve its full level of performance.

- Benefits of post-curing Torlon PAI parts: Torlon PAI grades attain their maximum strength, toughness and wear-resistance when post-cured at specific conditions of temperature and time. Under the correct conditions, the polymer also achieves its midpoint glass-transition temperature (Tg) of 282o C (540o F).

- Annealing PEEK, Ultem PEI, Ryton PPS and other advanced polymer parts: The transition from the melt phase to a solid form can create residual stresses that affect dimensional stability, especially in thick-walled parts. The correct post-annealing procedure can correct this. Parts are heated to a temperature above the material’s Tg then cooled slowly to a defined point below the Tg, relaxing the material and relieving internal stresses.

- Quality-focused shop floor environment

An injection molder’s routine production practices are key contributors to consistent part quality and delivery reliability. These are good indicators of a strong day-to-day shop floor quality culture:

- A climate controlled shop reduces variation caused by ambient temperature swings and humidity variation.

- Closed-loop material handling for transferring pelletized resin from shipping containers to dryers and on to the injection molding machine minimizes the risk of contamination. A robust transfer system also maintains the material’s correct dryness.

- Post-production tear-down and cleaning eliminates residue that remains on screws and barrels after a polymer is processed. If not removed, the residue will thermally degrade and shed black specks during subsequent production runs.

Purging compounds may work as a clean-up method for some plastics. However, advanced polymers melt at higher temperatures than purging compounds and are typically stiffer in the melt phase. This can leave degraded and unmelted residue in the barrel that can affect material quality in subsequent runs. The performance-critical nature of advanced polymer applications makes purging a short cut that does not justify the risk.Beyond the detriment to appearance, charred black specks in molded parts create stress risers that are prone to premature stress or fatigue failure.

Best practice dictates a full tear-down and clean-up of all parts of the molding machine including the barrel, nozzle and mold that contact the melted polymer after each production run to prevent charred contaminants.

- CNC machining

In-house CNC machining allows the injection molder to produce prototypes from stock shapes for validating design and material selection prior to building injection molding tooling. Machining also serves as a finishing step for parts with complex features or tolerances that cannot be achieved in injection molding tooling, or where a specific design feature is cost-prohibitive to incorporate into a mold.

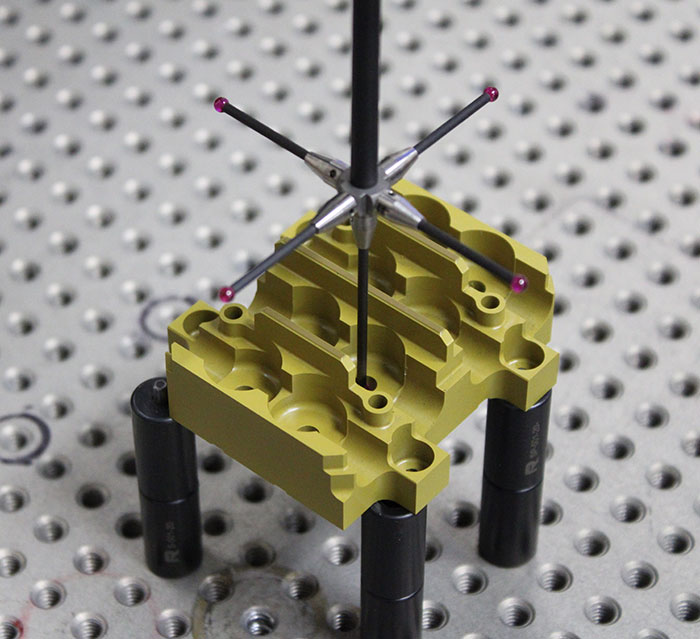

Analytical Capabilities to Support Scientific Molding and Quality Conformance

An analytical and test lab staffed with skilled engineers is a major asset for optimizing process conditions and the design of injection mold. It is also essential for validating conformance to the injection molder’s quality management system.

Investments in the following resources demonstrate the breadth of an injection molder’s ability to perform the analysis and testing required:

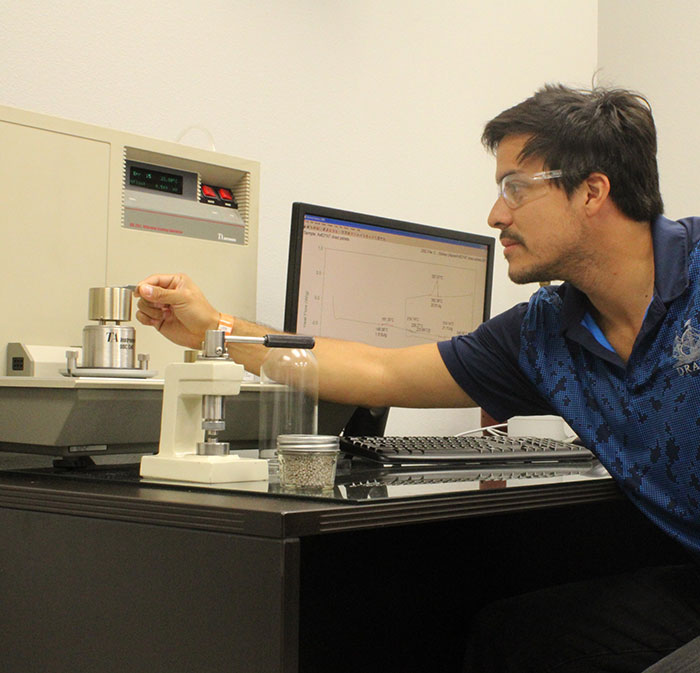

- Melt behavior analysis

Assessing the melt flow behavior of the many formulations of Torlon® PAI, PEEK, Radel® PPSU, Ryton® PPS and other advanced polymers helps pinpoint the ideal process conditions for injection molding consistently high quality parts. It also helps define the injection mold tool design that will yield parts with minimal internal stresses, good dimensional stability and overall quality.

- Comprehensive test equipment

These testing capabilities give an injection molder the resources needed to support a robust quality management system and trouble-shoot for potential variations in resin lots and in molded parts:

- Universal ASTM test machine to validate mechanical properties of resin lots and parts when required

- Non-destructive UT (ultrasonic) and CT (computer tomography) testing equipment to identify voids or other flaws in molded parts

- Moisture analyzers to determine the moisture content in resin prior to and during molding

- Density measurement equipment to confirm the identity of a material and that its full density has been achieved

- DSC (differential scanning calorimeter) to profile thermal properties of materials

In-house Mold Building and Maintenance

Expertise in melt flow technology for the various grades of high-performance polymers is essential to optimum tool design. Once the tooling is complete, a first-class injection molder will monitor and actively maintain the production tools. The ability to maintain and repair tooling in-house also helps get production back on track quickly.

Tool maintenance, managing schedules and locking down customers’ intellectual property and proprietary designs are important tasks that are much easier to control when new injection mold tools are built captively in the injection molder’s shop.

In addition, captive mold building allows quick mold adjustments, fine tuning of new tools and economical routine maintenance of existing mold tools. For especially tight tolerance parts, the ability to ‘walk into’ final dimensions and tolerances from steel safe conditions – removing minute amounts of steel to add polymer – during pre-production runs can be done more quickly and with far lower risk in a captive mold shop.

- Tool transfers

An injection molder’s ability to manage a tool transfer from another injection molder when circumstances make it necessary can be a valuable service. The capabilities required include a working knowledge of different metals and grades used to build tools, tool design expertise, and the machining equipment required for refurbishing and restoring tools to production status.

Quality Management System That Supports Customers’ Requirements

In most cases, advanced polymers are specified for applications in high technology industries, some of which have industry-specific quality requirements.

Certification to ISO 9001:2015 and full lot traceability are good baselines that satisfy many of those industry standards. However, certification to a more stringent industry requirement can benefit even customers that don’t require it. For example, a company whose quality management system is also certified to the more rigorous worldwide aerospace AS9100D(2016) standard will apply it to its production for all customers.

Advanced Polymers Require Advanced Molding Technology

High-performance polymers provide longevity and reliability for applications in environments that are beyond the limits of many metals and non-polymeric materials. Achieving their full performance in injection molded components requires high level expertise, experience-based processing skill, sophisticated production.

FAQs: Injection Molding Torlon® PAI, PEEK, Ryton® PPS and Other High-Performance Plastics

Is it difficult to find good injection molders for Torlon PAI and other high-end plastics?

While not as prevalent as commodity plastics molders, there are capable companies that specialize in high performance polymer injection molding. They continue to invest in the equipment, expertise and capacity to serve the growing demand for parts molded from these materials. Drake Plastics is an example.

Does adding fillers to Torlon like carbon fibers make it more difficult to injection mold?

Torlon PAI grades with reinforcing fibers and other additives such as lubricants require their own process conditions and tooling. The same is the case with other high-performance plastics. However, a capable injection molder will have the analytical tools to determine each grade’s melt and flow characteristics and establish process conditions and tool design and metallurgy accordingly.

Are their certifications that indicate if the molder is qualified to injection mold Torlon PAI and other advanced plastics?

Syensqo, the global producer of Torlon PAI resin, awards Certified Torlon Molder status to companies that demonstrate the ability to process the material at consistently high quality levels. RJG, a global leader in process control technology, also has a Master Molder® certification program that encompasses other advanced polymers as well.

What are some things to look for on the shop floor that would indicate a company’s expertise in molding Torlon PAI and other high-performance plastics?

Many things come into play: clean, organized operations with in-process control systems that monitor and adjust process conditions, closed-loop materials handling, resin-dedicated dryers, quality protocol that includes a full tear-down and polishing after each run. Injection molders who utilize all-electric machines and sophisticated analytical tools can confirm the required high quality of what they produce. More specialized and experienced companies design and build some of these capabilities in-house.

Parts injection molded from Torlon PAI, PEEK, Ryton PPS and other advanced plastics cost a lot. Are they worth it?

Engineers are specifying advanced polymers a growing rate because of their cost-effectiveness in specific applications. Examples: Torlon PAI bearing and wear grades last far longer than lubricated metals in oil drilling equipment. PEEK withstands harsh chemicals without corroding. Torlon PAI parts are used in satellites and space telescopes that must function flawlessly long term in extreme cold and radiation. Their value is based on performance that yields long term cost savings and reliability.