Cypress, Tex., May 2013 – Drake Plastics Ltd. Co. is now capable of producing quality prototypes using 3D printing technology. Drake adds this service to assist Torlon and PEEK customers’ new part development activities. This capability speeds up the process from idea to part and is a natural extension of Drake’s lean approach to business. Steve Quance, Drake’s founder adds, “3D Modeling and Additive Manufacturing in general are emerging process technologies which technical leaders like Drake must embrace.”

Rapid Prototyping enables Drake to enter the part development process one step earlier, eliminating wasteful iterations of machined prototypes and/or injection mold tooling rework. According to Len Wojtaszczyk, Drake’s Injection Molding Manager, “customers are increasingly asking for our involvement earlier in the design process. 3D printing allows us to show surface finishes and part features only the most experienced designers may catch before a tool is machined.”

Rapid Prototyping enables Drake to enter the part development process one step earlier, eliminating wasteful iterations of machined prototypes and/or injection mold tooling rework. According to Len Wojtaszczyk, Drake’s Injection Molding Manager, “customers are increasingly asking for our involvement earlier in the design process. 3D printing allows us to show surface finishes and part features only the most experienced designers may catch before a tool is machined.”

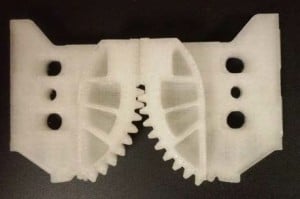

Drake’s 3D printing is proving valuable for complex prototype parts which will eventually be molded or machined from Torlon or PEEK.

Drake’s 3D printing is proving valuable for complex prototype parts which will eventually be molded or machined from Torlon or PEEK.

Drake’s capability supports .stl and .obj files from leading 3D design software programs. Drake models are produced from polylactic acid (PLA). Typical tolerances are 0.010″ (0.25mm) and provide a build size of 11.0″ L x 6.0″ W x 6.0″ H (285mm L x 150mm W x 150mm H).