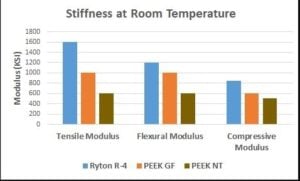

CYPRESS, TX–(Marketwired – March 14, 2017) – Drake Plastics Ltd. Co. announces the availability of extruded Ryton® R-4-240 PPS shapes from ½” up to 3″ diameter for machined parts. Ryton’s strength, stiffness and chemical inertness in a wide range of environments makes it suitable for applications ranging from the oil and gas and automotive industries to the aerospace industry. There are no known solvents for Ryton® PPS under 200°C. Additionally it offers a heat distortion temperature of 265°C, among the highest of the thermoplastics and room temperature stiffness that exceeds both glass reinforced PEEK and Torlon®.

CYPRESS, TX–(Marketwired – March 14, 2017) – Drake Plastics Ltd. Co. announces the availability of extruded Ryton® R-4-240 PPS shapes from ½” up to 3″ diameter for machined parts. Ryton’s strength, stiffness and chemical inertness in a wide range of environments makes it suitable for applications ranging from the oil and gas and automotive industries to the aerospace industry. There are no known solvents for Ryton® PPS under 200°C. Additionally it offers a heat distortion temperature of 265°C, among the highest of the thermoplastics and room temperature stiffness that exceeds both glass reinforced PEEK and Torlon®.

Ryton® has been used and specified for more than 30 years but its potential for parts has been limited to parts that can be injection molded or machined from compression molded shapes. Both of these options have technical drawbacks. Others have relied on other chemistry-modified PPS compounds that do not offer the same strength and stiffness as Ryton® R-4. These modified PPS compounds have been offered as equivalents but with mixed results. Ryton® R-4 extruded shapes offer strength and chemical resistance that exceeds even glass reinforced PEEK at much lower cost.

Ryton® PPS was first commercially produced in 1972 by Phillips Petroleum in Borger, TX. It was the first of the high strength, high temperature melt-processable polymers. Solvay (Alpharetta, GA) acquired the Ryton® business from Chevron Philips in 2015 to broaden its industry leading portfolio of high performance polymers. Today usage is growing through the development of new specialty compounds that offer additional improved toughness and steam resistance. Ryton® competes with both PEEK and high temperature nylons for designer’s attention in many industries where cost effective design solutions are paramount.

Despite ease of processing via injection molding, the highly loaded and branched structure of Ryton® R-4 made extruding shapes extremely challenging. Drake’s process engineers applying extrusion principles developed to process highly reinforced Torlon® compounds have demonstrated process capability up to 3″ diameter with plans to make larger shapes including plate in the future. According to Jeff Quance of Drake Research, the process development unit of Drake Plastics, Ryton® R-4 posed some initial process challenges but he sees the opportunity for expanding beyond 3″ and including the newly developed impact modified grades of XE5030 and XE4050.