High strength plastics have grown in use as engineers in high technology industries face the dual challenge of trimming weight by eliminating metals while extending the service life of components from which they are made.

Applications in aerospace and spacecraft equipment are under particular scrutiny given the importance of light weight and uncompromised reliability. In the chemical processing and oil and gas industries where equipment failure means costly production interruptions, light weight combined with resistance to severely corrosive operating environments are major benefits that high strength plastics can provide compared to metals. Lightening the physical load on mating components can also reduce frictional wear and extend functional life beyond the capabilities of even lubricated metals.

Torlon PAI Has the Highest Strength-to-Weight Ratio Among Melt-Processable Polymers

Among the strong, lightweight thermoplastic polymers that can be melt processed by injection molding and extrusion, unfilled or “neat” Torlon PAI ranks at the top with highest strength-to-weight ratio. A key benefit of all grades is the ability to retain their strength at high temperatures that rapidly diminish the physical properties of other polymers. The different fiber reinforced and bearing and wear grades of Torlon PAI add even higher levels of strength to the unfilled grades.

Important Mechanical Properties of Torlon PAI

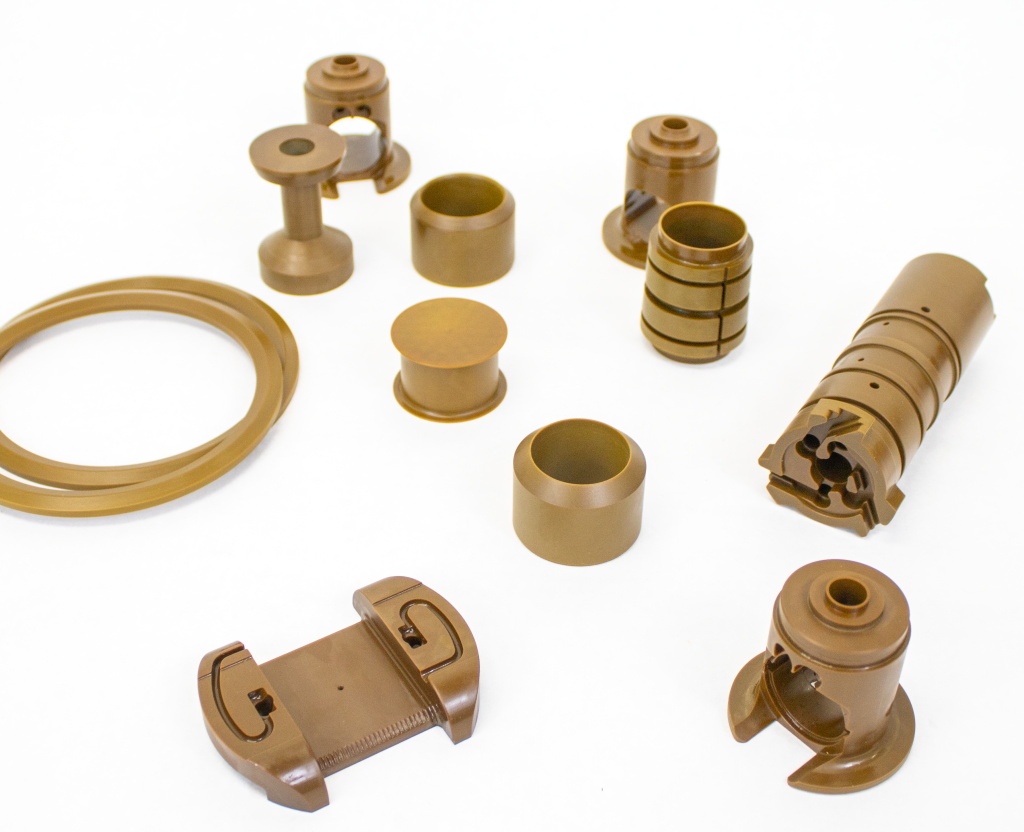

The various grades of Torlon PAI excel on the key properties that define strength and stiffness in comparison to PEEK and Ultem PEI, two other polymers often considered for these properties (Table 1).

Flexural modulus of unfilled Torlon 4203 measures 5,030 MPa (730,000 psi), exceeding that of unfilled PEEK by over 35%. In grades reinforced with 30% glass or carbon fiber, Torlon PAI values are more than 13% higher than PEEK formulations. Compared to another 30% glass fiber reinforced polymer, Torlon 5030 PAI’s flexural modulus of 11,700 MPa (1,300,000 psi) exceeds that of Ultem 2300 PEI at 9,000 MPa (1,300,000 psi).

Compressive strength is a critical property for applications that experience high point loads. Comparing 30% glass-reinforced grades, the compressive strength of Torlon 5030 is over 55% higher than GF30 PEEK and 19.5% greater than Ultem 2300.

Tensile strength is another important physical property where Torlon PAI, across a spectrum of grades, shows superior performance to PEEK, Ultem PEI and PPS.

Torlon PAI Retains Strength at Elevated Temperatures

At high temperature extremes, Torlon PAI retains strength and stiffness levels beyond the capabilities of other thermoplastics. This characteristic is particularly important in components associated with jet engines, rocket propulsion systems and semiconductor manufacturing processes that must maintain structural integrity in high temperature environments.

Engineering note: Glass transition temperature (Tg) or a material’s softening point is useful in comparing high-performance thermoplastics’ retention of strength and stiffness at high temperature extremes. The Tg of Torlon PAI is 280º C (536° F). By comparison, the Tg of PEEK is 150º C, and the highest temperature-resistant PEEK grade has a Tg of 170º C. Ultem PEI, another modified polyimide, has a Tg of 218º C, still well below that of Torlon PAI (Table 1).

Creep Resistance, High Tg and Low CLTE Contribute to Torlon PAI’s Dimensional Stability

Torlon PAI is recognized for its resistance to creep, or deformation under load over time, particularly at very high temperatures. This characteristic of the material can be related to its compressive strength and Tg, two other properties where Torlon PAI also excels. The creep resistance of Torlon PAI is especially beneficial for applications that must maintain their structural strength under high physical loads and temperature extremes long-term.

Engineering note: Torlon PAI’s low coefficient of linear thermal expansion across all grades is an asset for applications exposed to extreme operating temperature changes. It is particularly important for sealing and structural components in cryogenic equipment for propulsion systems where precise dimensions must be maintained while traversing extreme temperature swings.

Torlon PAI Has High Strength Plus Bearing and Wear Resistance

Unfilled Torlon PAI produced by Syensqo (formerly Solvay) offers inherently high strength and resistance to frictional wear in mating components. Several grades also have additives that extend wear life and boost mechanical strength.

To support customers on certain grades no longer provided by Syensqo, Drake Plastics compounds high strength bearing and wear formulations from 100% Torlon PAI resin and offers them as machinable stock shapes and injection molded parts. They are based on Syensqo’s original grades and were co-developed with the resin producer.

Torlon 4301 PAI is a high modulus polyamide-imide containing graphite and PTFE for improved wear resistance. This general purpose bearing and wear grade of Torlon PAI has an excellent balance of strength and impact resistance. It offers 10 times more wear resistance than non-reinforced Torlon 4203 and has a CLTE that approaches that of many metals.

Torlon 4275 PAI has a graphite and PTFE formulation that yields a lower wear rate than Torlon 4301 PAI under most PV conditions. Its bearing and wear performance compared to Torlon 4301 is particularly notable at high PVs, making it a frequent choice for high speed applications.

Drake 4435 PAI, previously offered by Syensqo as Torlon 4435 PAI, contains PTFE as well as graphite carbon fiber which boosts its structural strength. It is often specified for sliding wear applications. The high modulus grade exhibits low wear under most PV conditions and performs very well at high PVs. Its thermal expansion rate (CLTE) is also the lowest of the PAI wear grades.

Drake 4630 PAI, formerly Torlon 4630 PAI, outperforms all other PAI grades on wear resistance in non-lubricated high PV applications. Its proprietary combination of graphite and PTFE provides the lowest wear at velocities over 100 ft per minute (FPM) and it performs well even at PVs over 150,000 psi-FPM.

Drake 4645 PAI, previously offered as Torlon 4645 PAI, ranks with the 4630 grade on high wear resistance but is a particularly good option for high PV applications that are externally lubricated for heat dissipation. With its proprietary carbon fiber and PTFE formulation, Drake 4645 PAI has performed well at PVs of 600,000 psi-FPM.

Chemical and Radiation Resistance of Torlon PAI

Thermoplastic applications in high technology industries often involve exposure to severe environments that can degrade properties. Torlon PAI has proven its ability to withstand many of these conditions.

Applications include structural and bearing and wear components for space-based satellites that require long term dependability when exposed to radiation. Torlon PAI grades are also specified for high strength components exposed to plasma and chemicals in semiconductor manufacturing processes. Seals, valve seats and similar bearing and wear and structural components made from Torlon PAI also provide long-term reliability in down-hole oil and gas equipment.

As is the case with any material, application variables such as chemical concentration, temperatures, and the stresses from applied loads can vary widely. While guidelines are available, it is essential that applications in any material including Torlon PAI are tested to validate performance under actual in-use conditions.

Applications of Torlon PAI

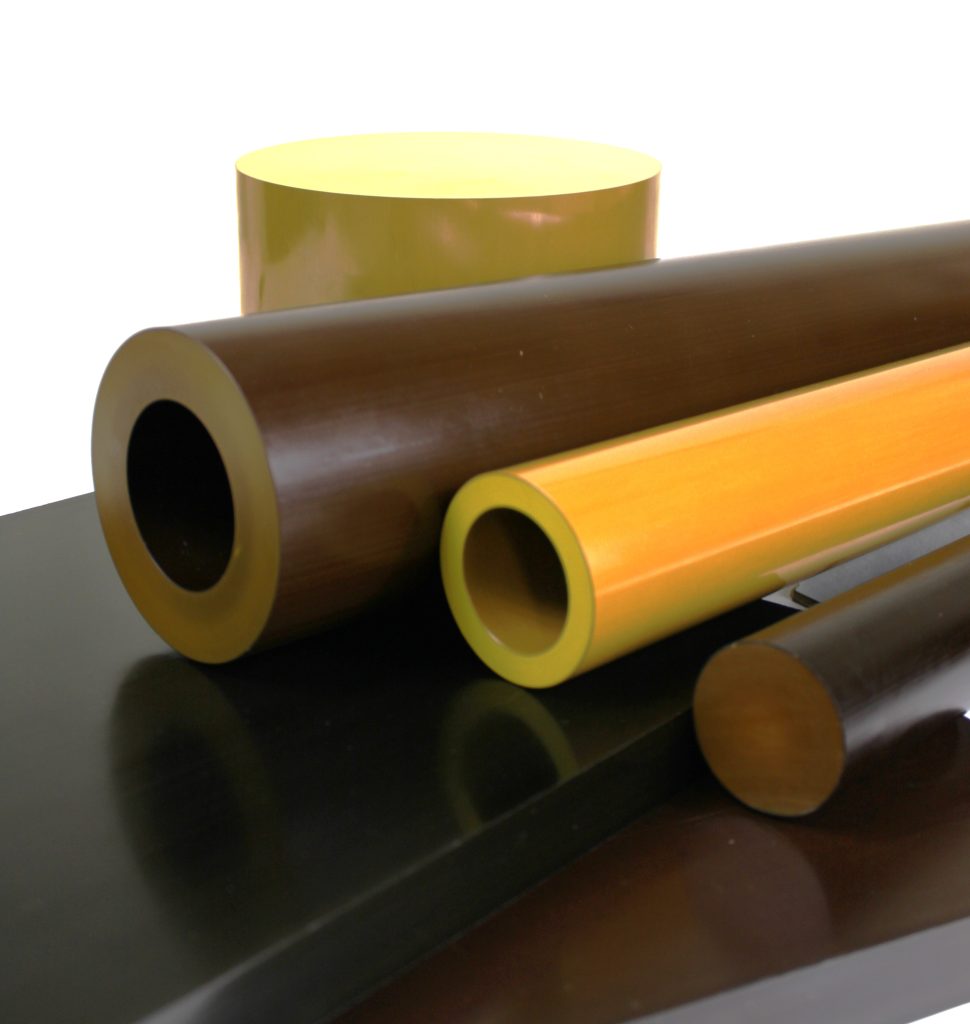

A family of Torlon PAI grades from Syensqo, the leading global PAI resin producer, offer unique property profiles for diverse applications that must function long-term under a variety of extreme conditions. The ultra-high performance capabilities of these formulations have led to their use as replacements for metals, especially where light weight and longevity in severe environments are important factors. The development exceptionally large extruded rod diameters, plate thicknesses and seamless rigid tube OD/ID combinations by Drake Plastics has also broadened the application range of various Torlon PAI grades in machined parts.

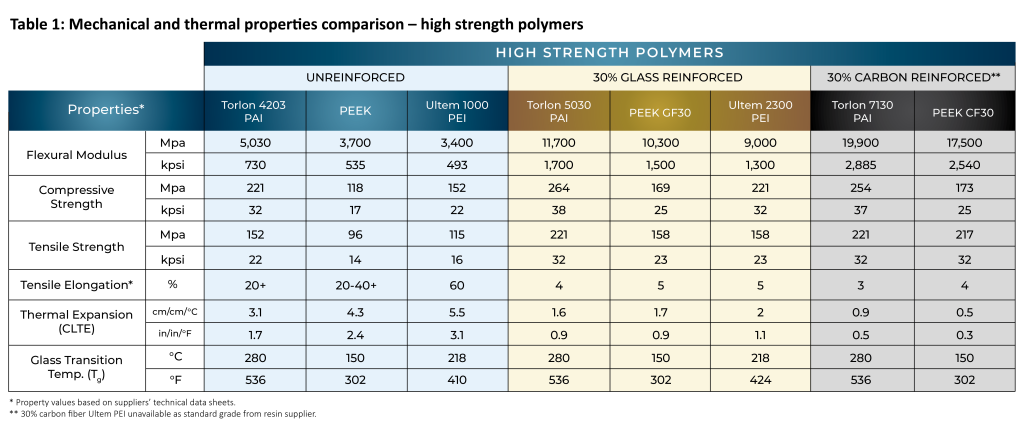

Major applications for the high-strength advanced polymer in both injection molded and machined forms include:

Aerospace and Spacecraft Equipment

The environment for equipment components can range from cryogenic conditions to extremely high temperatures, and include high stresses and exposure to hydraulic fluids, jet fuels, rocket propellants and other corrosive chemicals. Torlon PAI has numerous structural and bearing and wear applications that perform well in these conditions, including bearings, bushings, seals and fasteners.

Semiconductor Manufacturing and Test Equipment

Applications in this industry benefit from Torlon PAI’s dimensional stability, compressive strength, resistance to process chemicals and plasma, and strength retention at high temperatures. The various fiber reinforced and unfilled grades of the ultra-high performance polymer also eliminate the risk of metallic contamination. Typical applications include test sockets, chamber probes, wafer handling tools and fixtures.

Oil & Gas Equipment

Torlon PAI performs well in the hot, corrosive, high pressure down-hole environment where longer functional life of components means greater productivity through fewer shut-downs for repairs and replacements. The array of Torlon PAI applications in this severe service environment include structural components, seals and valve seats and a number of other bearing and wear components.

Torlon PAI Can Be Machined or Injection Molded

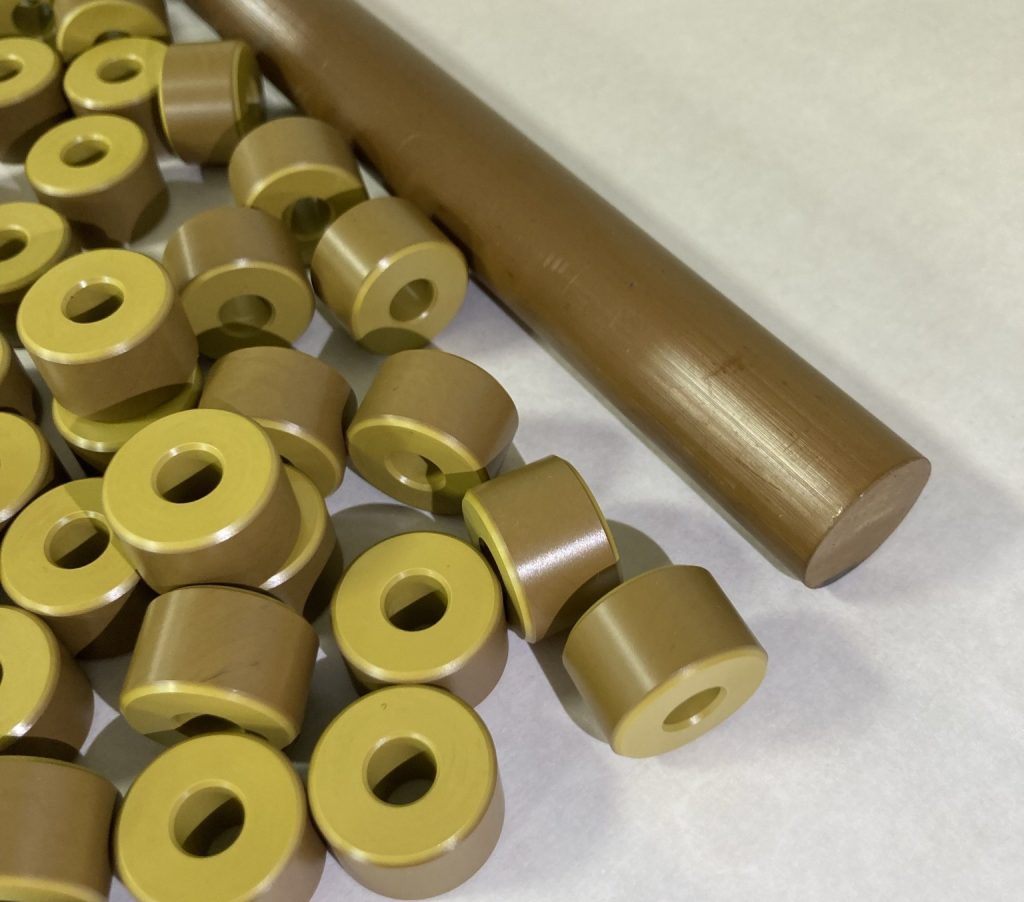

Their availability in pelletized resin and in a wide range of stock shapes and sizes means Torlon PAI grades can be converted into an unlimited range of component configurations.

The development of exceptionally large extruded rod diameters, plate thicknesses and seamless rigid tube OD/ID combinations by Drake Plastics has also broadened the application range of various Torlon PAI grades in machined parts.

Injection molding is typically most practical for high volume production. Machining of stock shapes can achieve more complexity and more highly precise tolerances. It is also well-suited to production volumes that don’t justify investing in injection molding tools. Without the need for tooling changes, prototype parts to test design modifications can also be machined in short lead times. In addition, post-machining of injection molded parts can add features that are too complex to achieve with injection tooling.

Both production methods in concert with the properties of Torlon PAI can yield complex precision parts with strength rivalling some metals. Each method has its specific attributes:

Efficiency: With injection molding, design features are integrated into tooling. Parts ejected from the mold usually require few or no secondary operations. High speed CNC machining of a part occurs automatically in multiple steps. However, for appropriate production quantities or for reasons of part complexity, machining can be a more viable production method compared to the investment required for injection molding tooling.

Injection molding also minimizes material consumption per part compared to machining. Material loss in machining though can be minimized by using an efficient stock shape size relative to the finished part configuration.

As an example, Drake Plastics produces Torlon PAI parts by injection molding and by machining. The company maximizes material efficiency in machining for its own and its customers’ operations by extruding an exceptionally wide range of sizes in Torlon PAI rod, plate and rigid tube. It also offers custom sizes. This capability helps balance costs between injection molding and machining and can defer or negate the need for investing in production injection molds.

Parts Have Consistently Precise Tolerances and Repeatable Quality

Injection molding and machining turn out components in all grades of Torlon PAI with consistent dimensions and precise tolerances. Machining has the edge on the precision tolerances that can be achieved. In some cases, machining is also used to add precision features to a molded part.

Mold Design Can Add Features That Facilitate Metal Replacement

With a capable mold builder, tooling can be designed for molded-in inserts and other features that add structure and functionality to Torlon PAI components. The same features can be added to machined parts as a post-production operation. In both cases, these added features help achieve parts with the lighter weight and wear and environmental resistance of Torlon PAI over metals without compromising the required structural strength.

Torlon PAI Offers Multiple Performance Benefits for High Strength Applications

Torlon PAI grades combine high strength with dimensional stability, bearing and wear properties and environmental resistance at temperatures beyond the capabilities of other thermoplastics. Available as injection molding pellets and machinable shapes, the ultra-high performance polymer can be transformed into virtually unlimited part configurations. Its attributes have led to its specification for components that must function dependably and long-term under extreme conditions.

Torlon PAI has more structural rigidity in unfilled and fiber reinforced grades as measured by the flexural modulus of all three materials.

Tg is the temperature at which a material softens. It is particularly important for structural components that are exposed to high temperatures even for short periods. Torlon PAI’s Tg is higher than any melt-processable thermoplastic.

Drake compounds certain PAI grades using 100% Torlon resin under an agreement with Syensqo, the PAI resin producer. This allows customers to maintain availability of the specialty PAI resin grades after Syensqo discontinued their production.

Because of its radiation resistance and its performance at cryogenic and very high temperatures, Torlon PAI has already been used successfully in deep space telescope systems and satellite and rocket propulsion equipment.

Stock shapes in unfilled, bearing and wear and fiber reinforced grades made from 100% Torlon resins are available under the Torlon PAI and Drake PAI brands. Drake Plastics is a leading advanced polymer extruder that stocks numerous rod and plate sizes and Seamless Tube® in many OD/ID combinations.