Drake extruded Ultem PEI stock shapes offer excellent thermal resistance, hydrolytic stability, high strength and stiffness, flame resistance, high dielectric strength, UV resistance, and broad chemical resistance.

- Thermal performance – Ultem withstands extreme temperatures better than nearly all other high-performance polymers. It retains superb strength and stiffness, even at temperatures as high as 390°F/ 200°C. Ultem 2300 has a glass transition (Tg) temperature of 419°F / 215°C and an in-flow coefficient of linear thermal expansion (CLTE) value of 1.1 E-5/°F (1.98 E–5/ °C), which is comparable to aircraft grade aluminum. As noted previously, the cross flow CLTE for Ultem 2300 is 3 X higher.

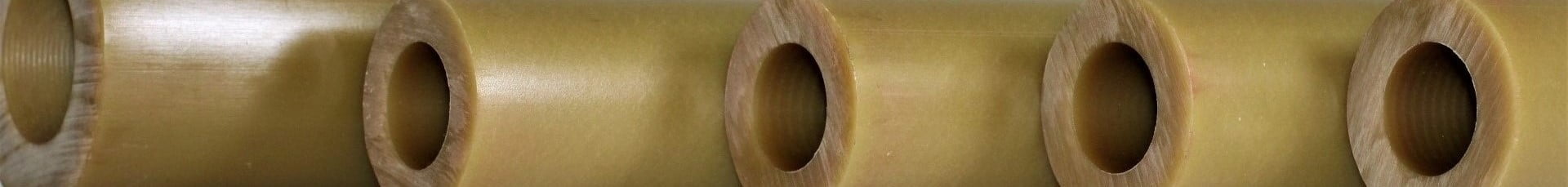

Ultem™ 2300 Seamless Tube

Chemical resistance, high strength and excellent thermal properties make it suitable for pumps, medical components, insulators and more.

Ultem™ 2400 PEI

Ultem 2400 PEI is a polyetherimide amorphous plastic that is reinforced with 40% glass fiber content.

Ultem™ 4001 PEI

Ultem 4001 PEI is formulated with PTFE as an internal lubricant. It gives engineers and designers the high performance inherent with the polyetherimide polymer coupled with significantly more wear resistance.

PEI is inherently flame resistant (V-0 rated) and low smoke generating. The excellent thermal properties of Ultem PEI make it a good fit for parts and components that must handle long-term exposure at elevated temperatures.

- Excellent strength and dimensional stability – Ultem PEI on its own offers outstanding strength and stability;Seamless Tube enhances these properties in the “hoop” direction with continuous flow and fiber orientation. The hoop strength gives Ultem Seamless Tube a clear advantage in parts or components under high internal or external pressure and loading. This is particularly true of 2300 (30% Glass Fiber) and 2400 (40% Glass Fiber) grades, and why reinforced Ultem grades are a common choice for structural components. Ultem Seamless Tube is a clear choice for structural components, containment tubes, coil bobbins, bearings, insulators, and rollers.

- Outstanding hydrolytic stability – Ultem PEI remains remarkably stable, even when subjected to steam and long term exposure to water. PEI’s low moisture uptake (1.21% by weight at saturation) and stability make it a compelling polymer option in the most demanding environments.

- High dielectric strength – Ultem possesses excellent electrical properties. At 770 V/mil in oil and 630 V/ mil in air, Ultem 2300’s dielectric strength makes it a natural choice for insulating components, electrical connectors, coil bobbins, terminal blocks and housings.

- Strong and tough before and after machining – Ultem is a cost-effective choice for machined parts. It retains its thermal, mechanical, and electrical properties after extensive machining and after extended exposure to high temperatures or harsh environments. The fiber orientation which are the result of Drake’s novel Seamless Tube process enable machined parts to withstand OD or ID radial stress that is unachievable in parts machined from Rod. Where and how the fibers are aligned dictates strength.

What are common applications of Ultem:

- Oil and gas components that are exposed to thermal conditions beyond what most other polymers can handle.

- Chemical processing components and equipment

- High temperature insulators.

- Electrical insulators and isolators

- Pump and valve parts.

- Medical device components.

- Structural and electrical components, with aerospace being a major focus. Ultem PEI’s rigidity and strength make it a good choice for structural components at elevated temperatures.

What are the advantages of using Ultem™ Seamless Tube?

Ultem 2300 and all Ultem PEI grades are versatile, high-performance polymers in their own right, but when parts start as Seamless Tube instead of Rod, they have several additional advantages. Some of these benefits include:

- Reduced waste – With Seamless Ultem Tube, there is no ID to drill out. That means a lot less waste during machining, which serves both of your “green” initiatives- environment and pocketbook.

- Reduced machining time and tooling wear – Drilling is often cited as the slowest of machining operations. Seamless Tube does not require drilling, only machining the ID to final size and tolerance. This not only saves machining time which saves money, it does not require drills, eliminating both the operation and the consumable tooling expense. Since Ultem 2300 is reinforced with glass fiber, tooling wear and machining time can be considerable when drilling stock rod. And if drilling to fast, cracks can result.

- Improved strength – Ultem Seamless Tube performs better than stock rod and plate in several ways. For one, it offers improved strength and stiffness in the hoop orientation. In independent burst tests Seamless Tube offered twice the rupture strength that they could achieve in the same part when machined from rod. That is an important consideration for components placed under internal or external pressure and loading.Drake Plastics closed loop extrusion process and tight processing windows and precise parameter controls ensure void and porosity-free material. Uniform flow throughout the cross section and helical fiber orientation gives Drake Plastics Seamless Tube using Ultem PEI a tremendous strength advantage for radial stress loadings, whether force is applied internally or externally. How the fiber is oriented within a part or shape is an excellent indicator of strength in that orientation.

- Improved dimensional stability – Parts machined from Drake Plastics’ Seamless Tube offer improved dimensional stability. The coefficient of linear thermal expansion (CLTE) of the OD and ID closely match resin data sheet in-flow values. This is due to Drake Plastics’ unique process for producing tube which results in uniform fiber orientation around the circumference. Many resin companies only report CLTE values in the fiber flow direction. Sabic does an excellent job of telling the ‘whole story’ in their Ultem products by also reporting crossflow CLTE. In the case of Ultem 2300, crossflow CLTE is 3X higher for the same temperature range.Low radial CLTE due to the fiber orientation means improved dimensional stability, which is critical when considering part finish and fit, particularly for components that are thermally cycled or incorporated into metal assemblies.

- Better tolerance control – Machinists report better tolerance control, especially roundness and concentricity when starting with Drake Plastics’ Seamless Tube over both rod and plate stock. When cylindrical parts are machined from rod, machinists complain about OD’s “shrinking”. This happens because plastics take up considerably more volume when they are at melt temperatures- and shrink when they are cooled. When the plastic that formerly supported the material above is removed, the remaining material is unsupported and “collapses” toward the center. This is the shrink effect that machinist observe. Round parts machined from plate become oval as soon as supporting material is removed. This is because extruded fiber filled plate has a very pronounced X-Y fiber bias which results in anisotropic properties and big differences in X-Y strength, CLTE, etc. Starting with Drake’s Seamless Tube eliminates these problems, enhancing the final part’s dimensional stability and protecting from costly yield loss.

Drake Plastics can produce Ultem Seamless Tube in a variety of sizes, with more than 50 different OD & ID combinations currently possible. We stock frequently requested sizes in response to demand, with modest minimums on a Made-to-Order basis for other sizes.