Engineers designing components for equipment that must operate under extreme conditions are often left with a very narrow field of material choices. Factors such as extreme temperatures, rapid temperature swings, cryogenic environments, corrosive chemicals and frictional load can severely limit the dependable service life of both metals and plastics. Extreme physical loads applied to components under these same conditions further narrow the range of viable options.

While the tendency may be to focus on metals for such engineering challenges, Torlon PAI has proven itself with a solid history of successes under severe operating conditions. The advanced polymer has a history of extending the reliable service life of components compared to metals particularly where there is risk of excessive frictional wear from dynamic loads. Further, its performance is typically coupled with cost benefits both in production and by minimizing the need for replacements due to excessive frictional wear on metal parts.

What are Torlon’s Benefits Compared to Metals?

One of the benefits of designing with Torlon PAI is that it is a family of materials with formulations tailored to different operating conditions. While the unfilled or neat grade has impressive properties, the addition of 30% glass or carbon fiber boosts its strength when applications require it. Bearing and wear formulations are also available that extend the wear life of the unfilled and the reinforced versions of the PAI polymer.

The following summary of performance factors indicate how Torlon PAI stacks up compared to certain metals that it has often replaced in demanding applications:

Specific strength

Among melt-processable high-performance polymers, Torlon PAI is in a class of its own on strength and stiffness. It also retains more of its strength at extreme temperatures. When compared to metals, its strength-to-weight ratio, also termed specific strength, is very favorable (Table 1). This combination of light weight and structural rigidity has positioned Torlon PAI as dependable material for many applications where aluminum, steel or bronze might be more traditional choices.

The PAI polymer’s high compressive strength also sets it apart from many other thermoplastics and adds to its viability as a material candidate for load-bearing applications where metals might otherwise be considered as the only option.

Wear resistance

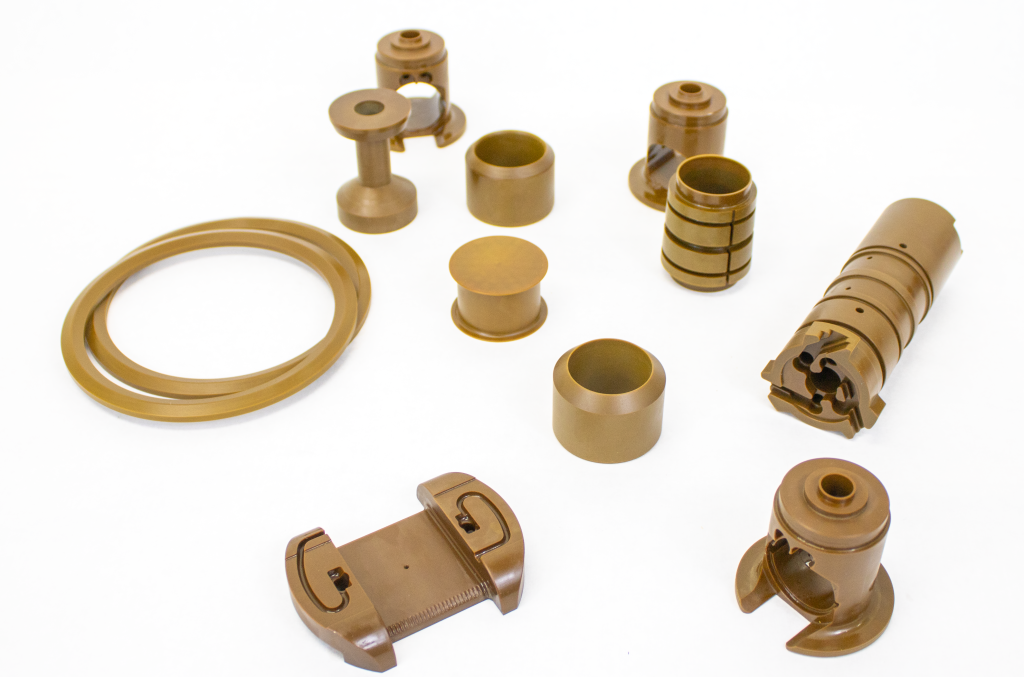

The Torlon PAI polymer has inherently high resistance to linear and rotating frictional wear under high loads beyond the capabilities of even lubricated metals. Moreover, Torlon bearing and wear grades have been developed to provide a step up in longevity for such components as bearings, bushings and seals in rotating equipment. These formulations have replaced traditional metals and delivered significantly longer service life in equipment where unplanned production shutdowns have extreme cost consequences.

Performance at temperature extremes

Torlon PAI has had decades of dependable performance in components exposed to extreme temperature environments. It retains a high level of its inherent toughness in cryogenic conditions where impacts can shatter many metals. At the opposite extreme, its glass-transition temperature (Tg) or softening point of 280o C / 536o F far exceeds that of other melt-processable polymers. This attribute enables Torlon PAI to withstand levels of extreme heat in applications where metals had once been the only alternative.

Chemical and environmental resistance

Many applications have been specified in various metals because of their resistance to certain chemicals. Torlon PAI, however, has the inherent resistance to a range of chemicals that make it a metal replacement candidate, especially where certain metals including titanium and steel fall short. The polymer also exhibits exceptional resistance to radiation which, along with its light weight, has led to applications on equipment deployed in deep space.

Engineering note: Chemical resistance is not a definitive property. Material suppliers can provide general guidance in this area. However, any polymer’s environmental resistance can be affected significantly by multiple variables including temperature, concentration and physical stresses. For this reason, specifiers are always advised to test Torlon PAI and any other material in finished components under actual operating conditions to validate performance.

Processability and production economics

Melt processability as a thermoplastic provides Torlon PAI a definitive production advantage. Metals are typically restricted to machining, powder metal sintering or stamping to produce parts. Torlon PAI however is most commonly converted into precision components by injection molding – a process that is especially cost-effective for high unit volumes – or by precision machining stock shapes extruded from the polymer. The melt extrusion process for shapes also affords a wide range of cost-efficient sizes of Torlon plate, rod and rigid tube that minimize material loss in machining.

What are Typical Applications Where Torlon PAI is Used Instead of Metals?

Torlon PAI’s inherent properties and the evolution of performance-enhanced grades have spread specifications for the polymer across these traditional and emerging high-technology industries:

In the operating environments for aircraft and spacecraft, material performance is mission-critical and long-term reliability is essential given the complexity of repair and replacement and the risks associated with part failure. Light weight for efficient fuel consumption, performance retention through extreme temperature swings and resistance to propellants and radiation are all requisites for materials in this industry’s challenging applications. Torlon PAI measures up to the criteria with multiple advantages over metals and a history of successful applications in bushings, thermal and electrical isolators, hydraulic system components and mechanical devices.

Torlon PAI’s high compressive strength, rigidity, wear resistance and tolerance to fuels and lubricants lend stability, lighter weight and longevity to components for race cars and other high-performance vehicles. The advanced polymer can also function dependably without lubrication in many applications. Its performance profile has led to specifications for Torlon in suspension bushings, turbocharger and supercharger components, and transmission seals and thrust washers.

The oil and gas industry subjects equipment and components to a combination of pressures, temperatures, frictional wear and chemicals that exceeds the capabilities of most metals and plastics. Given the stakes involved in maintaining production and avoiding unplanned maintenance and replacement shutdowns, the long-term dependability of materials for these components is paramount. Torlon PAI has established a track record for reliability and longevity over metals in equipment used in different segments of this industry including exploration, off-shore drilling, production and transportation. Ball seals, activation seats, poppets, well bore enlargement tool components, frac balls, sliding vanes and high-temperature, high-pressure cement flappers are among the typical applications for the advanced polymer.

Torlon PAI offers inherent electrical and thermal insulation and isolation properties that metals cannot provide. This characteristic coupled with its high strength has resulted in Torlon specifications for machined and injection molded connectors and other components for large battery equipment that plays a vital role in energy storage and metering. In wind turbines, load-bearing gear box components and rotor hubs rely on Torlon PAI over metals for long-term wear resistance and low noise output that metals cannot offer.

Thermoplastics used in nuclear power installations must withstand radiation exposure without losing their physical properties. In testing by an industry-commissioned laboratory, very few plastics retained their performance at 106 rads and greater. Glass fiber reinforced Torlon 5030, however, maintained the required level of properties at 109 rads, the highest level of exposure in the industry’s testing protocol.

In this high-technology industry, plastics naturally dominate over metallics as materials for components in contact with wafers and microchips. Torlon PAI grades have been developed with different combinations of performance attributes to serve these applications in the various phases of chip production.

For applications such as reticle pins where high purity is essential, Torlon resin-based Drake 4200 PAI combines the necessary low ionic impurities with high dimensional stability needed for the precision machined parts.

Glass-reinforced Torlon 5030 rod is machined into chamber hardware that require structural strength at high temperatures, while components that need less rigidity are routinely machined from unreinforced Drake 4200 PAI and Torlon 4203L. Chamber probes are also machined from these grades because they withstand the plasma environment and allow process monitoring that is free from electromagnetic interference.

At the final testing stage, test sockets machined from unfilled Torlon 4203L and glass reinforced Torlon 5030 provide different levels of resistance to compressive set and wear based on engineering requirements.

A major advantage of Torlon PAI over metals in weaponry is the polymer’s inherent resistance to corrosion and degradation in an operating environment where moisture, chemicals, lubricants and propellants are involved. The high strength, dimensionally stable polymer also affords lighter weight, a benefit for weapon portability and fast deployment in the field. Applications that capitalize on the properties of different Torlon PAI grades include guided missile radomes, igniter cups, fins, wings, and cable supports.

Torlon PAI is specified for many military aircraft components for the same reasons it is chosen over metal for commercial aircraft applications. Naval vessels also benefit from the wear and corrosion resistance of Torlon PAI in bearings and bushings that must perform reliably under extreme dynamic loads.

Does Processing Affect the Performance of Torlon PAI?

Torlon PAI is a high-temperature resistant polymer with a relatively narrow ideal melt temperature range. Maintaining tight controls on process pressures and temperatures is essential to prevent overheating or extended residence time that can cause degradation of properties. The optimum process conditions also minimize the risk of charred material on the surface of molded parts, and within extruded shapes – a problem that becomes evident in machined components.

In addition to maintaining the correct melt processing parameters, post-curing under controlled conditions is also an essential step for maximizing Torlon PAI’s strength, toughness, wear, and chemical resistance.

Qualified molders and shapes extruders will have the state-of-art process control technologies and equipment that yields consistently optimum material properties and quality. They will also maintain a bank of post-curing facilities with ample capacity and precision controls to fulfill routine and spike demand. Drake Plastics, for example, is globally recognized as a leader in Torlon shapes extrusion and has achieved Certified Torlon Injection Molder status from Syensqo, the Torlon PAI resin supplier. The company has designs and builds much of its equipment for processing the advanced polymer, as well as the post-curing capabilities to achieve optimum performance in Torlon PAI parts and shapes.

Have Applications Peaked for Torlon PAI as a Metal Replacement

High-technology industries rely on materials that couple strength with lighter weight, chemical and corrosion resistance, electrical, thermal and radiation resistance and longevity under static and dynamic loads. For many applications, metals are not an option, or they pose limitations that require complex solutions. Examples are common in the aerospace, semiconductor manufacturing, alternative energy and defense industries. While specialty metals may play a role, producers of Torlon PAI and other advanced polymer resins see a growing list of applications in these fast-growing arenas. They also continue to develop grades with properties for new applications that emerge – and that metals by their intrinsic nature cannot readily satisfy.

Torlon as a thermoplastic polymer offers lighter weight and a higher strength-to-weight ratio compared to many metals. It also resists frictional wear even unlubricated, and has thermal and electrical insulation and isolation properties that metals cannot match.

While most thermoplastics fall short, qualified test laboratories serving the nuclear power industry have shown that Torlon retains properties very well at 109 rads, the highest level of test exposure. This robust capability has led to structural and insulating applications for Torlon in satellites and deep space telescopes.

Torlon parts can be made by melt processing the pelletized resin, principally by injection molding or extrusion. Components can be precision-machined from extruded shapes. The ability to produce high quantities of parts to exact dimensions by injection molding is benefit compared to production methods for metals.

Torlon PAI does require expertise and specialized process equipment, control systems and post-curing capabilities to ensure good quality parts and extruded shapes. Although the field is limited, companies such as Drake Plastics who specialize in Torlon extrusion, machining and injection molding continue to invest in ample capacity to stay ahead of the fast-growing demand for critical parts. They also work closely with the Torlon PAI resin supplier in assessing potential long-term growth from global markets and new applications to ensure the capabilities for reliable supply.