To meet the diverse requirements of the industries we serve, Drake Plastics has developed the world’s most versatile line-up of ultra high-performance polymers in the widest selection of machinable shapes and lean, cost-efficient sizes. Our materials portfolio covers the spectrum of Torlon® PAI, Victrex and Solvay KetaSpire® PEEK, Ryton® PPS, AvaSpire® PAEK and Ultem™ PEI grades. In addition, Drake’s CNC machining and injection molding capabilities provide customers with ample capacity for prototyping, small runs and high-volume production requirements. We are also committed to developing the new products and configurations needed as our customers’ application requirements change.

Industry Applications and Drake’s Material Selection Support

Application environments and operating conditions differ widely from industry to industry. Drake Plastics’ Development Team welcomes a collaborative approach with customers to help pinpoint the material grade and production technique best suited to each application. Our track record demonstrates our success in helping engineers and specifiers achieve the best balance of performance and production efficiency for countless applications in technology-driven industries including:

Extreme operating conditions and the need for long term reliability make Drake Plastics’ ultra high-performance polymers ideal materials for aerospace applications.

Aircraft: Torlon PAI , Ryton R-4 PPS, Ultem PEI and PEEK couple their different levels of physical properties with the light weight, chemical resistance, thermal isolation and electrical insulation properties needed for thermal isolators, bushings, screws and tubing. Glass-reinforced Ultem 2300 is specified for structural components based on its performance and compliance with industry smoke and flame ratings. Carbon and glass-reinforced Torlon PAI and PEEK mimic the dimensional stability of metals and perform under the extreme and sudden temperature swings encountered in exterior lighting housings. Bearing and wear grades of these ultra high-performance polymers also afford along life for sector gears and rollers.

Spacecraft: Drake Plastics’ high-performance polymers have a strong track record in meeting the critical specifications for aerospace materials used in manned and unmanned spacecraft. Depending on application requirements, Torlon PAI grades provide strength, stability at temperature extremes and load bearing and wear resistance for long term reliability in precision moving parts such as sector gears that deploy satellite reflector arrays. Strength, thermal and electrical insulation, chemical resistance and light weight factor into Torlon PAI’s specification for thermal isolators and hardware for mounting fluid and gas piping and insulation panels. Drake offers specialized grades of Ultem PEI as an aerospace material that offers high strength and EMI/RFI shielding needed for lightweight hardware and structural applications in satellites.

Long term reliability under high-load bearing conditions and quiet operation are key material selection factors for wind-turbine components. Bearing and wear grades of Torlon PAI and PEEK deliver on both counts. Both polymer families have a solid history in sealing and isolation applications in hydrogen production and storage. They also provide the insulation and durability needed for large scale battery power storage units that capture energy from various sources for distribution on demand. In seals and couplings for tidal energy generation and geothermal systems, Torlon PAI and PEEK bring significant advantages over metals whose corrosion rate worsens with increases in naturally-occurring pH levels. Torlon PAI and PEEK have also demonstrated superior resistance to property degradation compared to many other plastics when exposed to high levels of radiation, an asset for reliability in components for nuclear power installations. Downstream power distribution equipment components are another application area where Torlon PAI, Ryton R-4 PPS, Ultem PEI and PEEK afford the strength, stability and electrical properties needed for long-term reliability.

Torlon PAI’s combination of high strength plus heat and wear resistance have increased the reliability of today’s high-performance engines and transmissions. In transmission seal rings, Torlon PAI replaced softer PTFE-based polymers and delivers longer life and improved reliability for these drive components. Automotive racing teams gain a performance edge from highly reliable, long-life suspension bushings, rollers and turbocharger and supercharger bushings made from the family of Torlon PAI grades. For reliable under-the-hood components, Ryton R-4 PPS provides high strength at temperature extremes and resists degradation from exposure to racing fuels and lubricants.

It takes a versatile family of high-performance plastics to serve the complex world of electrical and electronic equipment. Applications are widespread in just about every major industry, and each industry has a distinct end-use environment and material performance requirements. Drake Plastics satisfies this diverse demand with the widest range of grades, sizes and configurations of Torlon PAI, Victrex and KetaSpire PEEK, PAEK, high-temperature PEK, Ultem PEI and Ryton PPS available. Each offers a unique balance of physical, electrical and thermal insulation properties for connector blocks, insulators, fiber-optics connectors, ignition components, capacitors, bobbins, switches, connectors, sensor housings and similar applications used in many different industry sectors.

PEEK is often specified for medical instruments for its ability to withstand all sterilization techniques. Its X-ray transparency is also a benefit for components and instruments used in many medical and scientific procedures. Torlon PAI’s high compressive strength and wear resistance add up to long product life for peristaltic pump rollers and bushings for prosthetics. PEEK is used extensively for its dimensional stability and wear resistance in the miniature electrical motors built into surgical instruments. Implant grade PEEK has extensive uses in dental applications and spacers for spinal implantation. Both PEEK and Torlon PAI are also specified for components in laboratory equipment and analytical instruments that support the medical and life science industries.

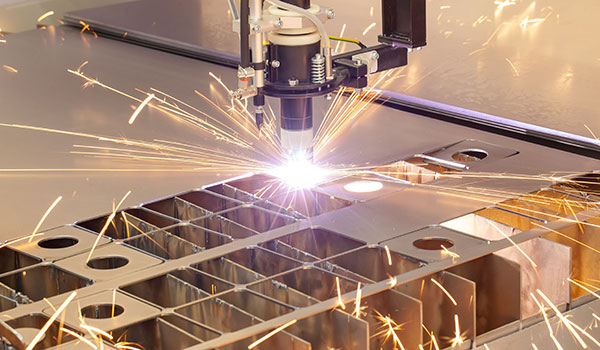

Metal production, forming, finishing and plasma cutting pose a tough set of operating conditions for thermoplastics. Drake’s ultra high-performance polymers stand up to the challenges. Torlon 4203 forming disks combine unmatched compressive strength and contact surface smoothness for high productivity and superior finish quality of CNC spun aluminum alloy reflectors. Templates, jigs, and forming components made from Drake’s high strength materials resist deformation during metal fabrication operations. Torlon PAI also delivers the thermal and electrical insulation properties necessary for plasma cutting torch components and consumables near the hot cutting tip. These high-performance materials even withstand the extreme temperatures required for use as components for electric arc and blast furnaces.

Precision and dependability under highly challenging conditions are essential factors in military and defense applications. Complex weapons system components must withstand fuels and aggressive chemicals and maintain precise dimensions under extreme spikes in temperatures and loads. Drake’s diverse line-up of Torlon PAI and PEEK, Ryton R-4 PPS and Ultem PEI all play roles in meeting these demands. Proven applications for Torlon PAI and PEEK include fins, wings, radomes and antenna mounts that contribute to weapons accuracy. Ryton R-4 PPS provides structural strength and electrical properties for insulators and receptacles in naval vessels and aircraft. Torlon PAI has a history of reliable performance in nuclear submarine ball valve seats and stern tube seals in a variety of vessels. In jet fighter auxiliary fuel tank connects, Torlon 4203L PAI withstands exotic fuels and high afterburner temperatures and performs flawlessly in the required 650psi/45Bar pressure test.

The energy industry’s Oil and Gas sector generates some of the most punishing application environments for any material. Even in downhole equipment components, Torlon PAI, Ryton R-4 PPS, and PEEK have proven they can handle the chemicals, pressure and heat. Glass and carbon fiber-reinforced grades offer the high strength and stability needed for applications that see extreme pressures. Each of these ultra high-performance polymers has unique properties to meet application-specific requirements in downhole, rigging and refining equipment. Applications include valve seats, connector bodies, blazers, seals, and compressor valve components, as well as drillable HTHP cement flappers and electrical connectors. Drake also offers the strongest nonmetallic frac balls available which perform on less than 2% seat interference.

Semiconductors and computing chips are produced in hot chemical and gas environments that rule out metals and most thermoplastics. The components used for handling these nano-scale devices through production and final testing must also maintain highly precise tolerances during each process step. With their high strength and stability at extreme temperatures, resistance to corrosive chemical and plasma environments and their low level of ionic impurities, Torlon PAI and PEEK are ideal polymers for the precision test sockets and nests used in high-speed device testing equipment, for wafer handling tools in chemical washing, and for probes, nests and ferrules used in plasma etching.

Our Drake Plastics team is well-versed in industry regulatory requirements and can help customers facilitate material selection to ensure compliance. Our Quality Management System is certified to the worldwide aerospace industry’s AS9100D(2016) and ISO 9001:2015 standards, and we apply these quality procedures to all orders we produce.