What Are Cryogenic Materials?

Cryogenic materials resist embrittlement and function well at extremely low temperatures. A limited number of plastics fall into this category, and most are amorphous in their polymer structure.

Drake Plastics produces machinable shapes, precision machined parts and injection-molded components from several advanced polymers that perform well in cryogenic conditions. These high-performance thermoplastics maintain robust physical properties in environments where temperatures fall below -150 oC (-238 oF). Their ability to remain tough and compliant at cryogenic temperatures sets them apart from other polymers. This characteristic enables them to perform reliably at cryogenic temperatures in applications such as static and dynamic seals for systems involved in the processing, storage and transport of liquid nitrogen, hydrogen, oxygen and liquified natural gas, as well as structural components in spacecraft equipment.

Benefits of High-performance Cryogenic Plastics

The inherent benefits of high-performance polymers apply to a wide range of operating environments, including gases and liquids at cryogenic temperatures. Their advantages compared to other polymers and many metals at cryogenic temperatures include:

- Retention of elongation

- Toughness and fracture resistance

- Retention of fatigue strength

- Light weight

- Wear resistance under dynamic loads without external lubrication

- Dependable static and dynamic seal integrity

- Thermal insulation, electrical isolation

- Production versatility by extrusion, injection molding, and machining.

What Cryogenic Materials Does DRAKE Offer?

Drake Plastics offers extruded machinable shapes, precision machined components and injection-molded parts made from advanced polymers that retain a significant level of their properties and perform reliably in cryogenic applications. Each material offers different property profiles to satisfy the requirements of a variety of cryogenic applications. General characteristics of these materials:

- Torlon® PAI: Torlon PAI features superior structural strength at temperature extremes compared to other advanced materials. PAI polymer technology has led to the development of bearing and wear grades that greatly increase the functional life of components under dynamic load. The technology has also yielded formulations with carbon or glass fiber reinforcement that significantly boost structural strength over unfilled grades.

- Vespel® PI: Considered the ultimate in overall performance among advanced polymers, Vespel polyimide is available as machinable shapes and precision machined parts. Vespel SP grades and the higher strength co-polymer SCP grades are particularly well-suited to machined cryogenic applications. Direct formed parts are also available. Unfilled and bearing and wear grades meet the performance demands of both static and dynamic seals for cryogenic liquids as well as structural components in cryogenic conditions.

- Drake PCTFE: A high-performance fluoropolymer, PCTFE has been specified for decades in cryogenic liquid oxygen (LOX), liquid hydrogen (LH2), liquid nitrogen (LN2) and liquid natural gas (LNG) applications. Its properties include high strength as well as V-0 flammability and a high Limiting Oxygen Index (LOI) of 95 that improve resistance to combustion where ignition sources may be present. It also resists degradation of properties when exposed to radiation. This combination of performance benefits has led to rapid growth as a material for seals that must operate reliably at cryogenic temperatures in spacecraft equipment.

- Drake CryoDyn® CT-200: Developed for cryogenic liquid sealing applications as an alternative to PCTFE, CryoDyn is a PEEK-based material with the physical properties and chemical resistance that characterize the PEEK polymer. Research into the material requirements for cryogenic applications led to the development of a PEEK-based compound with a second polymer phase. The material technology enables CryoDyn CT-200 to perform at cryogenic temperatures that are beyond the capability of unfilled and other traditional PEEK compounds.

- PTFE and other standard fluoropolymers: Drake precision machines parts from PTFE and other fluoropolymers to complement its cryogenic materials product line. Fluoropolymers such as PTFE are often not considered to be high-performance materials, primarily because of their low strength. However, they are often the best material choice when impact strength, chemical resistance and cost are key considerations – and structural requirements are low.

Cryogenic Properties Data for High-Performance Plastics

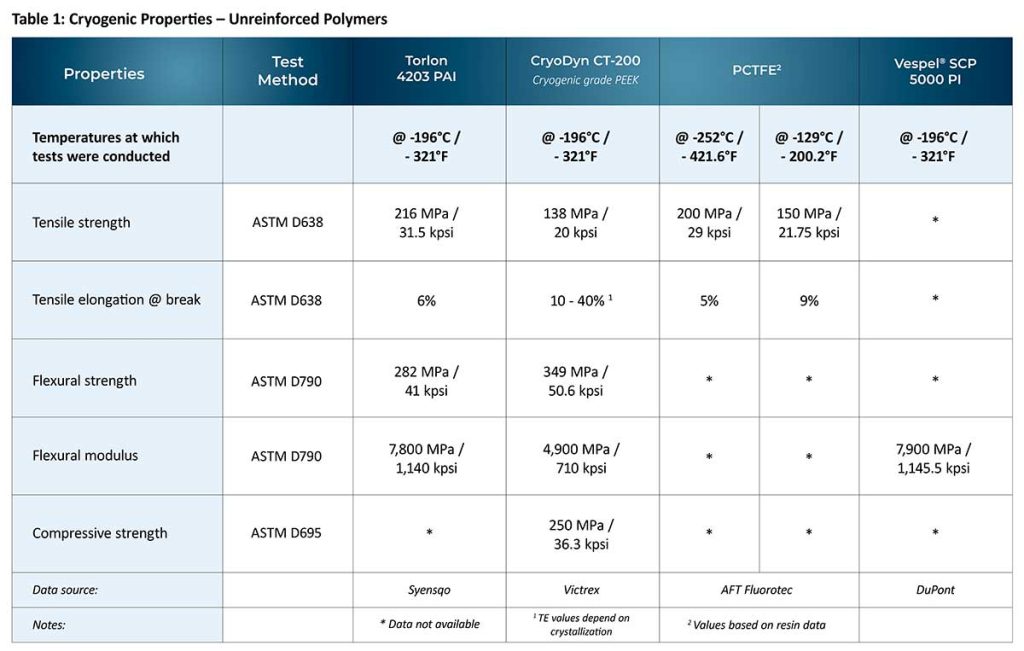

Resin suppliers generate property data based on standardized industry test specimens, test methods and test conditions. These standard data sheet tests are routinely done at ambient and elevated temperatures for all resin grades. However, only a few suppliers conduct property testing at cryogenic temperatures, and on only a limited selection of properties and grades. An example is the property data available on Drake’s CryoDyn cryogenic polymer and on PCTFE resin (Table 1). Also, test conditions can vary among suppliers of different resins. All these factors make direct comparisons of cryogenic materials properties data difficult.

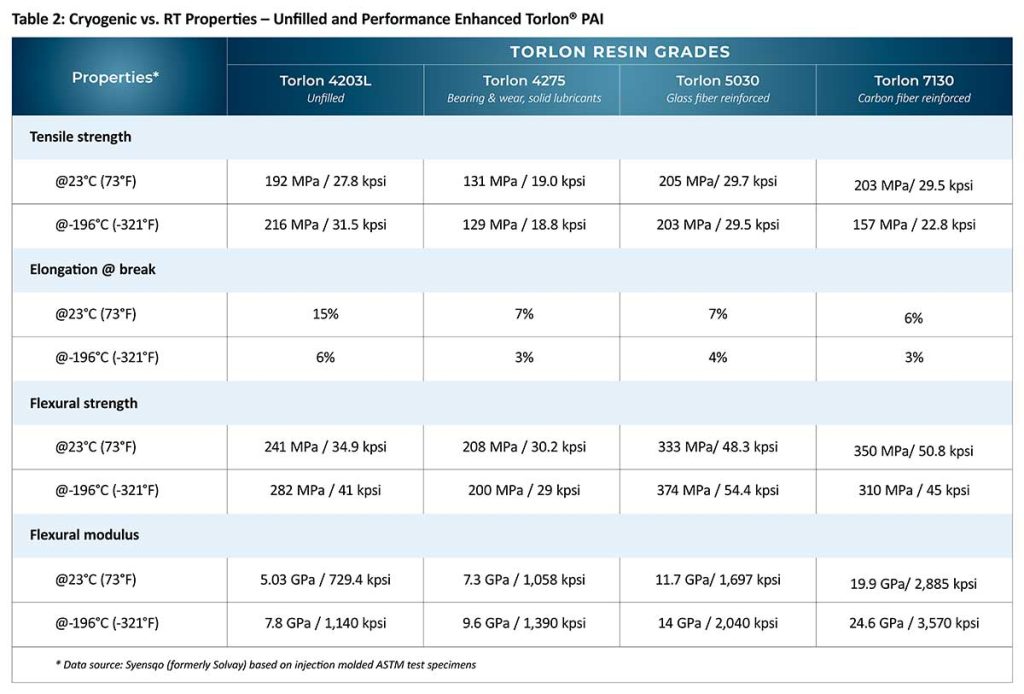

Nonetheless, it is possible to develop material options for cryogenic applications. In the case of Torlon PAI, mechanical properties data is available at cryogenic test temperatures for four different types: unfilled, bearing and wear-enhanced, and both carbon fiber and glass fiber reinforced grades (Table 2). The cryogenic properties data available on these representative grades can help assess the viability of similar formulations.

Typical Data Sheet Properties as a Material Selection Tool

The polymers Drake offers for cryogenic applications retain mechanical properties well at these low temperature extremes associated with liquid nitrogen, liquid hydrogen, liquid oxygen and liquid natural gas based on experience. Comparing their “standard” data sheet properties and factoring in the effects of these gases at cryogenic temperatures as outlined below can provide another useful starting point.

Complete properties data conducted under standard test conditions on all Drake materials is available in machinable shapes data and polymer suppliers’ resin data sheets.

Ultimately, best practice dictates that prototypes and production parts be tested under the application’s actual cryogenic operating conditions to validate performance in use.

How Cryogenic Temperatures Affect Material Properties

Exposure to extreme freezing temperatures affects several properties of all polymers to some extent. Materials typically become more rigid and exhibit a gain in flexural and compressive properties accompanied by a reduction in tensile elongation and impact resistance. Wear resistance often improves due to increased surface hardness and accelerated heat dissipation. Dimensional stability during rapid temperature transitions can also affect the integrity of static and dynamic seals.

While each application has its specific performance requirements, the following properties and how cryogenic conditions affect them are important in evaluating materials for extreme low temperature service:

Mechanical Properties

Cryogenic temperatures cause materials to become stiffer, increasing their flexural and compressive strength and modulus. At the same time, extreme cold reduces the tensile elongation and ductility of a material.

Application notes:

- The effect of cryogenic conditions on mechanical properties are important factors for structural applications in space flight equipment. While rigidity is increased, materials must have the resilience to withstand vibration and stresses during propulsion, recovery, docking, apparatus deployment and other operations.

- A significant increase in compressive modulus due to cryogenic temperatures is also an important engineering consideration for seals. High compressive properties may impede the ability of seals to conform to mating surfaces and achieve uniform contact.

CLTE and Dimensional Stability

A cryogenic material can experience proximity to hot ignition sources as well as extreme freezing temperatures in the vacuum associated with deep space. Traversing high to low temperature extremes can create a significant level of thermal expansion and contraction. A high-performance polymer material with a low coefficient of liner thermal expansion (CLTE) can provide the dimensional stability required for critical operating components such as vessels and pressure relief devices to function reliably. And unlike metals, the coefficient of thermal expansion for polymers is not linear; it increases with increasing temperature.

Data sheet values for the CTE of polymers are typically generated from -40o C to 150o C and expressed as a single data point. However, thermal expansion in polymers is non-linear. The values are lower at lower temperatures, and the actual CTE at cryogenic temperatures is lower than the “typical” values reported on data sheets. It is also important to note that in fiber reinforced grades the CTE is measured in the direction of fiber flow. CTE values measured in the crossflow direction are much higher, by as much as twofold.

Application notes:

- The coefficient of liner thermal expansion (CLTE) of polymers for structural parts and housings in spacecraft may differ from the thermal expansion behavior of materials in mating surfaces and fasteners. Materials with similar thermal expansion properties can minimize the risk of stress cracking due to significant dimensional changes from extreme and often rapid temperature variations.

- The CLTE of the materials used for mating surfaces in static and dynamic seals is also an important factor. Significant differences in dimensional changes over temperature swings from rocket launch conditions to extreme and rapid cooling can adversely affect sealing integrity. Therefore, system seal interfaces need to be considered at their cryogenic service temperatures and not only at ambient or assembly temperatures.

Impact Resistance

Low temperature extremes embrittle all materials to some extent. Some metals are more prone to shattering under these conditions than are high-performance plastics.

Application notes:

- A material’s ability to retain a good level of ductility in cryogenic conditions is important for structural components and housings in spacecraft equipment that can be exposed to strong vibration and impacts.

- Seals in liquid oxygen, liquid hydrogen, liquid nitrogen and liquid natural gas systems can be exposed to stress including impact during installation prior to cryogenic exposure. Materials with good inherent toughness can help avoid impact-related micro-cracks and surface defects that can become failure points when cryogenic temperatures create stresses from dimensional changes and service pressures or other forces that the system experiences.

Bearing and Wear Properties

High-performance plastics compounded with solid lubricant additives such as graphite, PTFE and carbon fibers perform well in cryogenic bearing and wear applications. in fact, their wear resistance often improves as their surfaces increase in hardness due to cryogenic temperatures. Additionally, the typical cause of polymer bearing failure – localized heat buildup – is usually absent in cryogenic tribological service.

Application notes:

- Applications in spacecraft equipment may have both structural and dynamic functions. For example, components may be designed with gears to assist in deploying or activating apparatus. Torlon PAI and Vespel PI grades compounded with solid lubricants like PTFE and graphite offer improved bearing and wear properties and are viable materials option for these applications. They eliminate the problems associated with external liquid lubricants that can solidify at cryogenic temperatures and form particulates that can contaminate operating components.

- The addition of glass or carbon fibers in Torlon PAI increases the material’s strength while maintaining the polymer’s inherent cryogenic toughness. In many cases these fiber reinforced grades – Torlon 5030 and Torlon 7130 – outperform their internally lubricated counterparts in many cryogenic wear applications such as sliding vanes.

- Dynamic seals in liquid oxygen, nitrogen, hydrogen and liquid natural gas processing, storage, delivery and transport applications also benefit from bearing and wear formulations of high-performance polymers. These advanced materials maintain their wear resistance under dynamic loads at cryogenic temperatures to provide the long-term sealing reliability required in liquefied gas handling applications.

Related Performance Benefits of Advanced Polymers

Advanced polymers have gained widespread use as cryogenic materials for components and seals in spacecraft equipment, and for seals and related applications in LOX, LH2, LN2 and LNG systems.

These materials in the form of machinable shapes, precision-machined components and injection-molded parts from Drake Plastics have demonstrated their ability to maintain robust mechanical properties under cryogenic conditions. Each material also offers thermal and electrical insulation and isolation and flammability ratings, which are important benefits for spacecraft and liquified gas equipment where the risk of combustion due to the proximity of ignition sources may be present.

Comprehensive data on flammability ratings and electrical and thermal properties are for Drake’s machinable shapes and the resins used to produce shapes and injection molded parts can be found in Drake’s resin data sheet.

In addition, the high-performance polymers Drake processes resist a wide range of chemicals. Each material is unique in this respect. Drake Plastics’ application engineers can help customers access the databases of its major resin suppliers for more detailed information on how chemicals and variable conditions of concentration, temperature, and stress affect the performance of components made from each polymer.