What is Vespel® Polyimide (PI)?

Vespel® is DuPont’s registered trademark for their high-performance polyimide (PI) parts and machinable shapes. Several grades have been developed with properties tailored to the performance requirements of extreme and diverse application environments.

How is Vespel® Polyimide Different from Thermoplastic Polymers?

Vespel® PI and similar polyimide polymers have a softening point or glass-transition temperature (Tg) that is very close to their decomposition temperature. For Vespel PI, this occurs at a point well in excess of 400 °C (752 °F). This translates to two significant differences between Vespel® PI and most high-performance engineering thermoplastics:

Performance: The strength and moduli of Vespel SP grades decrease in a nearly linear manner with increasing temperatures, while the properties of most high-performance thermoplastics drop significantly as they approach their softening point or glass-transition temperature (Tg).

Processability: Because of the very close proximity of their Tg or softening point to their decomposition temperature, polyimides like Vespel® PI do not have a thermoplastic-like melt phase that allows them to be melt-extruded into machinable shapes or injection molded into parts.

Vespel® is the ultimate in performance and dependability for critical service applications.

How Are Vespel® PI Machinable Shapes and Parts Produced?

To produce shapes for machining into components, Vespel® PI polymer in powder form is sintered or fused under high temperature and pressure by different methods, depending on the shape required. The sintering process itself is commonly used in powder metallurgy.

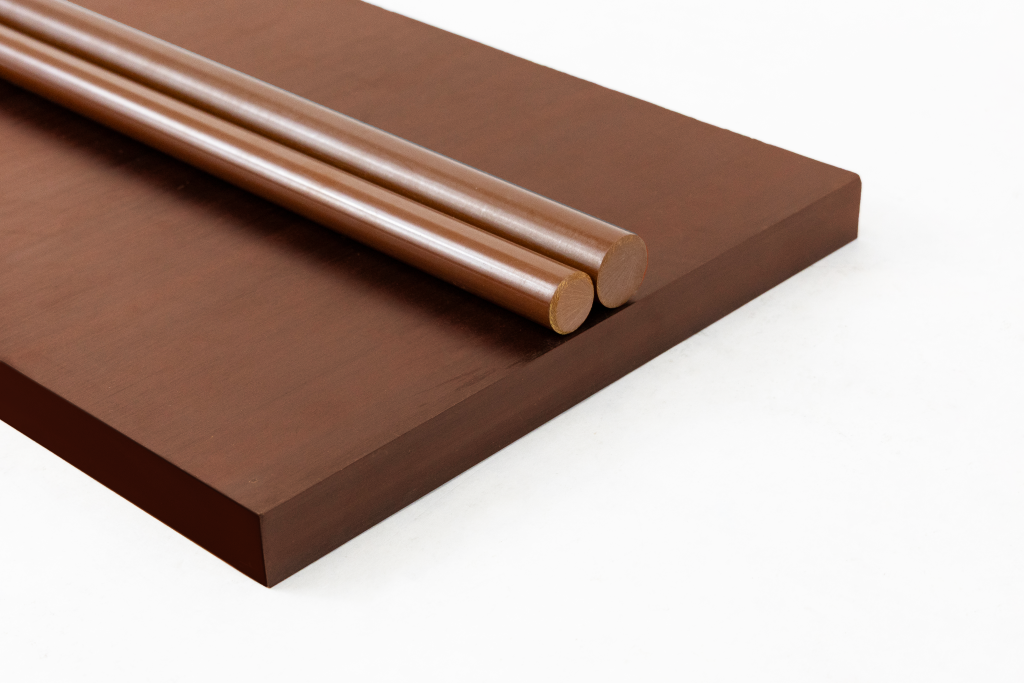

Vespel® PI rod is isostatically molded from powder, while machinable plaques and discs are compression molded. DuPont also offers parts made by direct forming. The process is more suited to high volumes of small parts. Regardless of the production method, all involve sintering at high temperatures and pressures, a process typically associated with powder metallurgy.

"*" indicates required fields

What Are the Key Physical Properties of Vespel® PI?

The polyimide polymer imparts a unique combination of properties that are inherent in all Vespel® PI grades. Certain grades are made with additives that improve specific properties.

Common features of all Vespel® PI grades include high property retention from cryogenic to extremely high temperatures. They resist wear and friction at high PV conditions in both lubricated and unlubricated components. Vespel® PI grades also have high structural strength, which translates to creep resistance even at high temperatures. Impact resistance, superior electrical properties and dimensional stability with a low coefficient of linear thermal expansion are among the other properties typical of the Vespel® PI product line.

Although sintered high temperature polyimides are typically considered to be brittle polymers with low elongation and low impact resistance, Vespel® SP grades offer uniquely higher elongation and impact resistance. These properties translate to machined components that are tougher and more resilient over their broad operating temperature range compared to parts made from other commercially available sintered polyimide products.

Various grades of Vespel® PI also meet the aerospace industry’s standards for low flammability and smoke generation. They can withstand exposure to a broad range of chemicals, including fuels, lubricants and hydraulic fluids used in aircraft. Thermal oxidative stability, low outgassing and radiation resistance also make Vespel® PI a reliable option for components in spacecraft and defense equipment.

Thermal Stability of Vespel® PI Properties

Another important performance feature of Vespel® polyimide grades is that they undergo thermal decomposition at high temperature extremes in excess of 400 °C (752 °F), rather than softening as temperatures increase. The loss of properties related to degradation of the Vespel® PI polymer is linear, in contrast to thermoplastics that exhibit a sharp drop in properties as they approach and traverse their Tg, and subsequently fall to zero when they reach their melting temperature (Tm).

Isotropic Properties Behavior of Vespel® PI Shapes and Machined Parts

Isostatic molding and compression molding yield isotropic properties, or properties that are equivalent along all axes within the Vespel® PI shapes made by these processes. This same isotropic behavior translates to parts machined from the shapes.

Direct formed parts exhibit anisotropic behavior, with properties dependent on the direction of the forming pressure applied. DuPont works with designers to set forming conditions based on performance requirements of the part.

DuPont offers an array of Vespel® PI grades. Their different compositions were developed to achieve performance improvements in specific areas.

The Vespel® SP product line comprises grades with graphite and fluoropolymers in various combinations to improve friction and wear performance over the unfilled Vespel® SP-1 grade. Fillers also contribute greater strength, dimensional stability and thermal stability.

Defined as next-generation polyimide, Vespel® SCP grades raise the thermal oxidative stability of the PI polymer and resist outgassing beyond the capabilities of SP products. Both unfilled and higher strength Vespel® SCP grades with improved bearing and wear properties are also available.

What Vespel® PI Grades in Machinable Shapes Does Drake Offer?

Drake offers machinable shapes in three unfilled and graphite-filled grades of Vespel® PI that serve a wide range of applications: Vespel® SP-1, Vespel® SP-21, and Vespel® SCP-5000.

An unfilled polyimide grade, Vespel® SP-1 provides dependable performance for machined parts that must operate at temperatures from cryogenic levels to 300 °C / 570 °F). In addition, Vespel® SP-1 can withstand brief temperature excursions up to 482 °C / 900 °F because it has no Tg or melting point measurable by standard methods.

Other attributes of Vespel® SP-1 include thermal oxidative stability with low outgassing, thermal and electrical insulative properties, and higher rigidity and ductility than filled grades of Vespel® PI.

The 15% graphite content in Vespel® SP-21 improves its friction and wear resistance over unfilled grades. This feature is behind its frequent use as a material for flanged and plane bearings, seal rings, and for sliding-wear applications.

Its flexural strength and flexural modulus are higher than unfilled Vespel® SP-1. It also excels on dimensional stability measured over thermal extremes, and retains its properties at higher operating temperatures of 350 °C / 662 °F. Like Vespel® SP-1, the SP-21 grade can tolerate brief temperature spikes up to 482 °C / 900 °F.

Described as a next generation polyimide, Vespel® SCP-5000 was developed for applications that require higher thermal oxidative stability than traditional grade of PI can offer. An unfilled grade, it has inherently high mechanical strength, dimensional stability and toughness. Vespel® SCP-5000 also has the chemical resistance characteristic of the polyimide polymer, along with dielectric properties that remain stable over a wide temperature span.

Drake Machined Parts in Vespel® PI

Drake applies its expertise in precision machining advanced polymers to the full family of Vespel® PI shapes. Resources include state-of-the-art CNC machining centers with up to 8 axis capabilities, and operators and engineers who are skilled in the production and inspection of parts to ensure consistently high levels of quality as well as on-time delivery.

Quality Management System Aligned with High Technology Industries

Aligning with high technology industry requirements for shapes and components made from advanced materials, Drake Plastics’ Quality Management System is certified to the worldwide aerospace industry’s AS9100D(2016) and ISO 9001:2015. The standards are applied to all customers, regardless of industry or region.

Vespel® is a registered trademark of E.I. DuPont de Nemours and Company