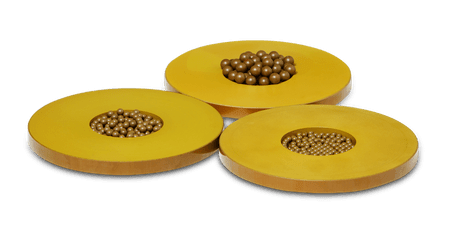

Torlon Balls and Roller Bearings

Standard Torlon Ball Sizes and Availability

Drake’s Torlon balls are manufactured to precision tolerances from Torlon 4203L resin and supplied with a polished surface ranging from 20 to 40 Ra in diameters from 0.125” to 0.625” (3.1 – 15.87mm). All standard English and Metric sizes are available from inventory for immediate shipment. Customs sizes and balls made from other Torlon grades and other high performance polymers such as PEEK are available with minimums.

Torlon Roller Bearings

Trolon Roller Bearings are made to customer specifications. Typically machined from extruded Torlon 4203 rod for smaller quantity requirements, they are injection molded to finished sizes as volumes increase and justify an investment in tooling.

Why Torlon 4203L for Balls

Why Torlon Ball and Roller Bearings

Torlon ball bearings have the PAI polymer’s advantages of excellent resistance to chemicals and wear from dynamic loads. In addition, bearing and wear resistant Torlon 4203L ball bearings can eliminate the need for external lubrication, an advantage over metals and often an important benefit for bearings in marine applications, food, pharmaceutical and electronics production and packaging equipment.

Compared to other thermoplastics, Torlon has far higher strength and load carrying ability, and retains its strength at higher temperatures. Torlon PAI is also highly dimensionally stable over extreme temperature changes, an important asset for reliable ball bearing operation where environmental conditions vary. This unique balance performance advantages has led to the use of Torlon ball bearings for a wide range of applications in diverse industries.

Torlon ball bearing advantages

- Resistance to deformation under high point loads

- Wear resistance – can eliminate external lubrication

- Dimensional stability

- Precision tolerances

- Strength and load carrying even at high temperatures

- Corrosion resistance

- Counter-face friendly

Torlon Ball Bearing Applications

Because of their long-term resistance to deformation under load even at elevated temperatures, Torlon balls are a common choice for industrial ball bearing applications. They are also used in the marine industry sail riggings for their high strength and corrosion resistance and headsail roller furlings. Torlon ball bearings in swivels carry heavy loads without deformation and allow sails to furl freely. Another marine application is in high-load boat traveller cars where Torlon ball bearings provide maximum load-carrying ability and rotate freely and reliably even under high lateral or cantilevered loads.

Typical applications

- Marine headsail roller furlings

- Marine swivel bearings

- Marine winches and swivels

- High-load boat traveller car ball bearings

- Industrial linear ball bearings

Complementary Bearing Products

As complementary products, Drake extrudes rod and Seamless Tube for the production of balls, roller bearings and bearing cages from Torlon and other high performance polymers to provide dissimilar mating surfaces. These complementary products are precision-machined and available in a wide range of sizes.

Torlon Check Balls

In automotive transmission valve applications, Torlon check balls withstand long term exposure to transmission fluids at high temperatures. Because they are more ductile, Torlon balls conform to the valve seal more closely compared to steel check balls, for better sealing integrity. And with their lighter weight, Torlon check balls afford lower inertia compared to steel balls for smother, quieter and more responsive shifting.

Torlon check ball advantages

- Better check ball sealing properties

- Elimination of wear on mating surfaces

- Lifetime performance