High Loads on Aerospace Sector Gear

Based on physical properties data, a major aerospace company chose 30% carbon fiber reinforced Torlon 7130 for a highly loaded sector gear. However, they were not aware that the resin supplier’s data sheet reported properties measured in the direction of fiber flow and reported values are not isotropic. Mold flow and FEA analysis of an injection molded part demonstrated the gear teeth would be considerably weaker than was assumed by using the strength values published in Solvay’s Data Sheet, regardless of gating.

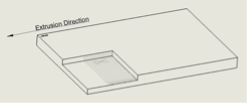

Drake’s knowledge of fiber orientation within our extruded Torlon 7130 plate enabled us to recommend part orientation so that the gear teeth under the highest stresses were parallel with the direction of the fibers. A part drawing was created which specified the parts’ precise orientation within our extruded Torlon 7130 plate to ensure consistent placement and performance.

Result: Test results consistently well above design minimums and multiple, flawless launches and deployments.