Impact on material properties and part performance.

An aerospace company purchased Drake extruded KetaSpire KT-820 CF30 30% CF reinforced PEEK plate to characterize the material and develop a material specification. They sent the plate to a major testing lab for sample prep and to measure physical properties. The property results were disturbing: very wide scatter, some respectable, but many very low in both strength and elongation.

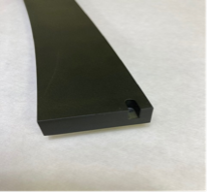

Drake requested the samples for analysis and discovered poor quality machining. We then provided machined specimens from the same lot of material with our typical 32 RMS/ 0.8 Ra or better finish for specimens. The resulting properties were excellent and highly consistent, demonstrating the critical importance of good surface finishes to the performance of high strength fiber-reinforced polymers with low elongations like the carbon fiber reinforced PEEK used for this application. Other frequently specified reinforced materials where surface finish plays a beneficial role include KetaSpire KT-820 GF30 and 450GL30 PEEK with glass-fibers, Victrex 450CA30 and KetaSpire KT820-CF30 carbon fiber reinforced grades, 40% glass reinforced Ryton R-4 PPS, and Torlon PAI 5030, 5060 and 7130 grades.

Result: Based on our standards, the customer updated their specifications for machined part finishes to realize these major consistency and performance benefits.