Frac Ball Performance & Reliability

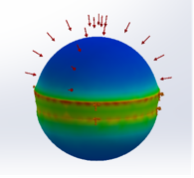

A major supplier of fracking tools and services came to Drake for a high strength, high temperature resistant drillable frac ball for a 60-zone system requiring less than 2% interference with the ball seats. Their drawings specified +/- .005”/ 1.27mm tolerances and sphericity. Drake FEA analysis backed up by testing determined that the tolerances as defined were much too wide for the parts to work reliably.

The strength needed for the frac balls required high fiber loading, which can negatively affect ductility and impact performance unless the parts have an optimal design for the severe application conditions. If they were slightly out of round, the high fiber content balls would shear fail under the extreme loads of hydraulic fracking.

Drake recommended and still produces high strength frac balls at less than 1/3 of the tolerance the customer originally requested in sizes up to 4.0”/ 100 mm. Their high fiber content coupled with much tighter tolerance control has ensured tens of thousands of successful deployments and zero failures.

Result: Flawless, reliable system performance. And the principal engineer mused, “in 30 years, I have never had a machined part suppler recommend tolerances 3 times tighter than we asked for.”