What is Drake PAI?

Two priorities spurred the development of Drake PAI products: A commitment by Drake Plastics to provide customers a dependable, ongoing supply of legacy products, and Drake’s commitment to offer materials to serve new applications and specialty requirements. When unforeseen external circumstances got in the way of those priorities, Drake and the resin supplier collaborated on solutions to clear the barriers.

Torlon® PAI Specialty Grades Transitioned to Standard Drake PAI Grades

Though infrequent, major resin suppliers may consider discontinuing specific grades or forms of polymers for various reasons. Case in point: Torlon® 4435, 4630 and 4645 resins developed by Syensqo (Solvay) for extrusion and injection molding. The materials serve narrow market niches requiring production volumes below those that can be produced economically in a large scale resin operation.

Rather than eliminating these grades, however, Syensqo elected to support their customers and continue them in collaboration with Drake Plastics. Drake’s Engineering and Development team then designed and built the specialized equipment for compounding these specialty PAI formulations for melt processing. The specialty grades compounded at Drake are made from genuine Torlon® PAI base resin produced by Syensqo.

Cooperation between the two companies has led to the ongoing economical availability of these three unique products that complement standard Torlon grades by providing different performance features. They will be sold as Drake 4435, 4630 and 4645 PAI, all made from Torlon® resin. The materials are available as extruded machinable shapes, machined parts and injection molded parts. The Torlon resin-based Drake PAI resin compounds will be tested and certified to the same standards as when previously offered under the Torlon tradename, ensuring customers continuity of both performance and quality.

Drake PAI Machinable Shapes, Thin Sheet and Film

Drake offers the former Torlon PAI grades under the designations Drake 4435 PAI, Drake 4630 PAI, and Drake 4645 PAI. They are comparable in performance and quality to the same products sold previously under the Torlon PAI tradename and they retain their numerical grade designations. All are available as machinable shapes, machined parts and injection molded parts.

Drake is also applying its compounding technology to the development of Drake 4200 PAI for extruded shapes and machined parts, also based on Torlon PAI resin. Its unpigmented high-purity formulation is ideal for semiconductor manufacturing equipment where low metallic content is essential.

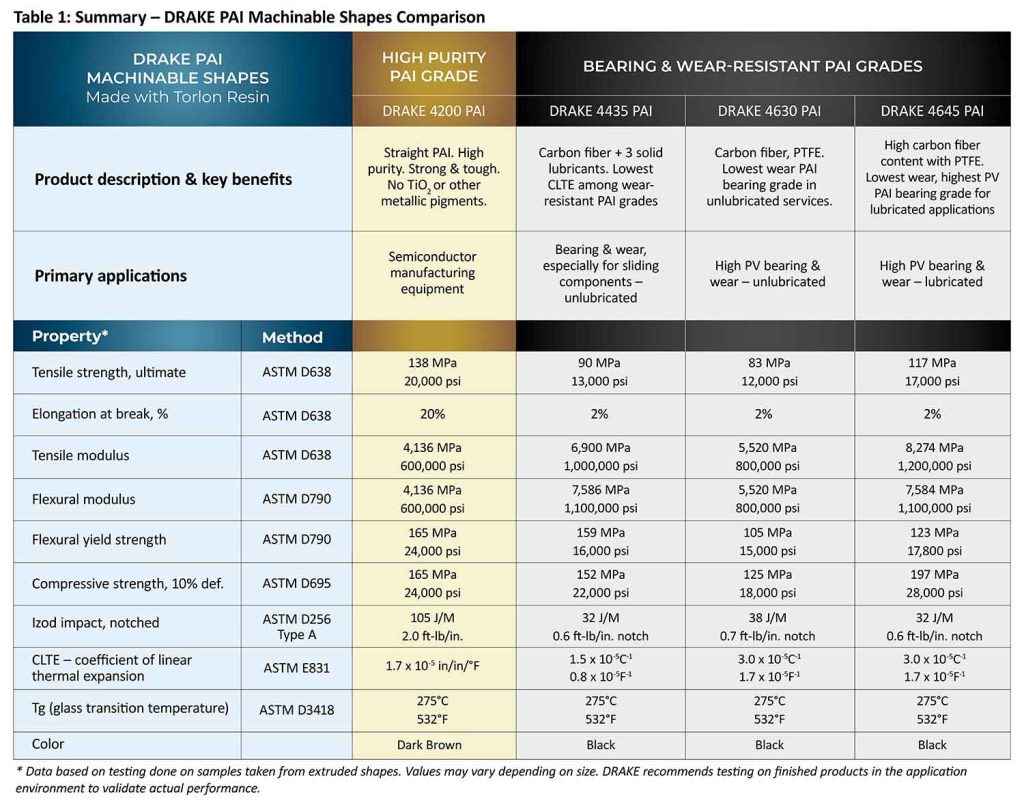

Table 1 provides a properties comparison of all four Drake PAI stock shapes grades. In addition to these products, Drake’s PAI portfolio includes Drake PAI thin sheet and film in variety of gauges for electrical and electronics applications.

Drake 4200 PAI: Previously available as Torlon 4200 PAI.

In addition to high strength and temperature resistance, Drake 4200 PAI offers similar performance to Torlon 4203 and Torlon 4203L. Brown in color, Drake 4200 PAI contains none of the TiO2 pigment that gives Torlon 4203/4203L a distinctive gold appearance. It offers exceptional plasma erosion resistance with dramatically lower bulk metal contaminants, especially aluminum and titanium. This higher ionic purity is of interest for components used in semiconductor manufacturing equipment.

Drake 4435 PAI: Previously available as Torlon 4435 PAI.

Drake 4435 PAI contains the same proprietary blend of carbon fiber and solid lubricants as Torlon 4435 PAI. These combine to provide high flexural modulus and low wear and friction properties, especially in sliding wear applications. Its wear rate is among the lowest of any PAI grade under most unlubricated conditions, and in high PV applications it offers improved properties over Torlon 4301 PAI. It is also dimensionally stable through temperature variations with the lowest CLTE of any PAI wear grade.

Drake 4630 PAI: Previously available as Torlon 4630 PAI.

Its physical properties and its wear resistance under a wide range of dynamic load conditions position Drake 4630 PAI as the highest performance high PV PAI wear grade. Its proprietary PTFE and graphite formulation delivers exceptional longevity in unlubricated high PV applications. Its wear rate is the lowest at velocities greater than 100 feet per minute (30.48 meters per minute) and it performs effectively at PVs greater than 150,000 psi-ft/min (5.2 MPa-m/s).

Drake 4645 PAI: Previously available as Torlon 4645 PAI.

Drake 4645 PAI offers the lowest wear rate of any PAI grade in lubricated applications. With a proprietary carbon fiber and PTFE formulation, it exhibits the lowest wear rate at all velocities where external lubrication is required for heat dissipation, loads, speeds, or for the gearbox or assembly in which components made from the material are installed. In actual applications it has withstood PV conditions of 600,000 psi-FPM (>20 MPa-m/s).

In addition to machinable shapes, the Drake PAI product line-up includes thin sheet and film made from PAI polymer. The commitment to support customers’ new applications drove the introduction of this unique PAI product form. Drake PAI thin sheet and film products are available in several thicknesses from 0.3mm to 2.0mm from inventory.

Drake PAI Certifications and Traceability

Drake provides no-charge certifications and lot traceability on each shipment of Drake PAI shapes and machined and injection molded parts. Please contact us for information on specific Drake PAI grades.