Torlon® polyamide-imide is recognized as the highest performance thermoplastic that is still melt processible. Torlon can be extruded into shapes and injection molded into custom geometries.

Depending on the grade, Torlon PAI offers a heat deflection temperature of up to 539°F (282°C), and affords unparalleled strength at high temperatures. Is has been used in many applications with continuous exposure to 500°F (260°C) for extended periods* and is stronger at 400°F (204°C) than other engineering resins at room temperature. Torlon PAI is also tougher and more impact resistant at cryogenic temperatures than other high strength polymers.

*Continuous Use Temperature (CUT) performance: See Thermal Stability in Solvay Design Guide to determine suitability for your application.

Its exceptional mechanical and thermal properties are the result of an extended curing process* which lengthens the PAI polymer chain and builds its molecular weight. Glass-reinforced and carbon fiber reinforced grades offer even greater stiffness plus enhanced thermal expansion properties. The wear grades offer unmatched performance over a wide range of temperature and PV conditions.

Torlon polyamide-imide is virtually unaffected by aliphatic and aromatic hydrocarbons, chlorinated and fluorinated hydrocarbons and most acids at moderate temperatures. It may be attacked by saturated steam, strong bases and some high-temperature acids.

*Drake Plastics cures all Torlon products prior to shipment.

"*" indicates required fields

Gears, rollers, plasma chamber hardware, wafer contact fixtures.

Electrical insulators, thermal isolators, valve seats seals, cams, gears, poppets and ball bearings.

High-temperature thermal/electrical insulators, burn-in/test sockets, valve seats, fasteners and activation balls.

Mechanical linkages, rollers, labyrinth seals, impellors, valve plates, vanes, back-up seal rings.

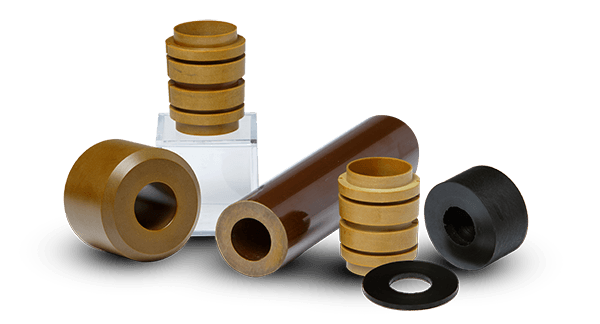

Wear Resistant Grades

4301

12% Graphite, 3% PTFE

High load Bearings, thrust washers, wear pads, seals, bushings, valve seats.

4275

Higher Speed Bearings & Bushings, Bearing Cages, Piston Rings.

4435

Now Available as Drake 4435 PAI

Sliding vanes, thrust washers and bobbins, piston seal rings.

Now Available as Drake 4630 PAI

Proprietary PTFE & Carbon Fiber

High PV bushings, bearings, sliding vanes, thrust washers

Now Available as Drake 4645 PAI

High PV lubricated bushings, bearings, sliding vanes, thrust washers