Bearing and Wear Resistance, Minimal Slip-Stick and High Strength at Working Temperatures to 200°F (93°C)

Drake HTT-200BG Performance

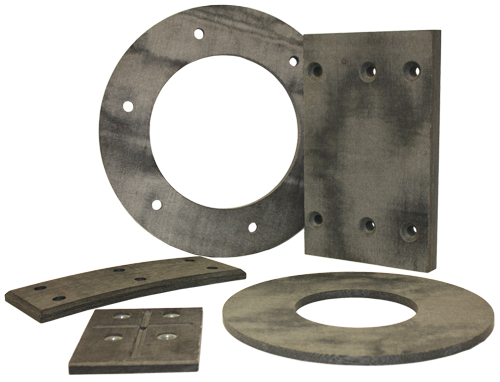

Drake HTT-200BG composite shapes offer enhanced bearing and wear resistance, and maintain their structural strength at working temperatures from -40o F to 200o F (-40o C to 93o C). In addition to minimizing wear, the material has an exceptionally low coefficient of friction compared to many other composites

A self-lubricating material, HTT-200BG is manufactured from thermosetting resins, a low friction woven textile, and uniformly dispersed molybdenum disulfide (MoS2) and PTFE solid lubricants. The formulation minimizes friction and wear, and reduces slip-stick and noise in oscillating or pivoting components under load.

Other characteristics of Drake HTT-200BG include its low coefficient of thermal expansion and the ability to withstand high edge and shock loads. It also features the high structural strength and toughness characteristic of all Drake thermoset composites.

Availability –

- Rod, plate, and tube in standard and custom sizes

- Many sizes available with no custom tooling charge

- Prices quoted on request

- Precision-machined parts

Typical Industry Applications

Its mechanical properties, minimal slip-stick and wear resistance make HTT-200BG an excellent option for wear pads, bushings, bearings, hydraulic cylinders and other components under dynamic load at working temperatures up to 200o F (93o C):

Industrial

- Metalworking and metal processing machinery

- Drilling and mining equipment

- Agricultural and wood processing equipment

- Pumps and hydraulic systems

- Materials handling and conveying systems

- Building and construction equipment, cranes

Oil and Gas

- CALM buoys

- Riser tensioners, iron roughneck components

- Blowout preventers, pipe stackers and rig walkers

- Booms, masts, winches

- Launch and recovery equipment

Hydropower

- Wicket, vertical gates

- Lock, miter gates; guides

- Servo motors

- Head covers

- Spillway trunnions, fish gates

Marine

- Propulsion and steering system components

- Stabilizers, stern tubes

- Winches, crane masts

- A-frames, LARS

- Rollers, skid pads